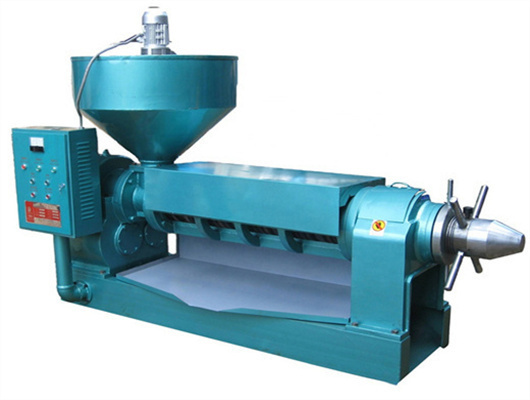

high oil yield victor 600 sunflower oil expeller in durban

- Usage: Sunflower OIL, Cooking Oil

- Type: Sunflower Oil Extraction Machine

- Production Capacity: 50-1000kg/h

- Voltage: 380V/50HZ

- Dimension(L*W*H): 2120*1610*2000

- Weight: 1360 KG

- Warranty of core components: Other

- Core Components: Pressure vessel, Gear, Bearing, Engine, Gearbox

- Oil type: Sunflower Oil

- Processing Capacity(t/24h): 9-11

- Motor Power(kw): 18.5 or 22

- Weight(kg): 1360

- Measurement(mm): 2120*1610*2000

- Oil Content of Dry Cakes(%): ≤7.6

- Spiral Axes Rotate Speed(r/min): 32-46

- Quality: ISO Certification

- Brand: Guangxin

- Delivery time: 20 - 25 Days

Maximize Your Oil Yield with Anderson

Victor-600™ Expeller® Press Rates Process Capacity (MTPD) Residual Oil Specifications Cold Press 12 - 18 10 - 14% Horizontal Drive, 100 - 125 HP Full Press 15 - 20 5 - 8% Horizontal Cage Length, 55 in. Extruded Material 40 - 60 5 - 8% Cage Diameter, 6 in. Twin Motor Super Duo™ 33 & 55 Rates Process Capacity (MTPD) Residual Oil Specifications

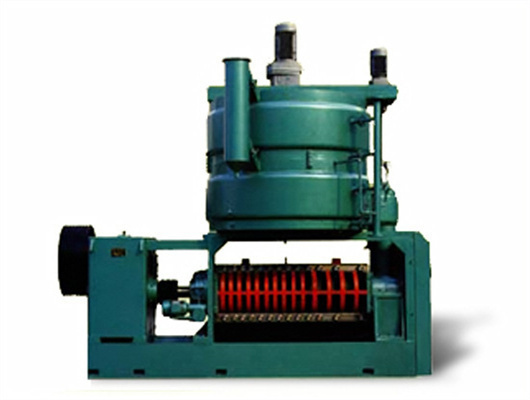

2.1.1 Description of the Sunflower oil Expeller. The main components of the oil expeller are frame, cake outlet, expeller housing, heating compartment, auger, hopper, auger pulley and shaft as shown in Figure 1. Various components of the oil expeller were designed using standard formula.

Vegetable Oil Expeller®

The founder of Anderson International developed and manufactured the first continuous mechanical extractor, trademarked Expeller®, in 1900. Its first use was on Linseed oil extraction at the Sherwin Williams Company. In 1907, the first Expeller® was exported to a Linseed plant in what is now Kranj, Slovenia. Since then, the Anderson Expeller

#sunfloweroil #sunfloweroilmachine #sunflowerseedhttps://www.oilpressing.org/oil-sunflower-press-machine.htmlE-mail: [email protected]/WeChat/Tel:...

Expeller Pressed Sunflower Oil vs Solvent Extraction Methods

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier.

The oil extraction by mechanical pressing is the most common method for continuous treatment of oleaginous seeds without solvent. Different types of presses can be used depending on the purpose (expeller, expander, and twin-screw extruder) and on the capacity range (3 kg h−1 to 150 t day−1). At the laboratory scale, many authors have highlighted the effect of operating parameters (screw

Napa Valley Sunflower Oil, Expeller Pressed, Organic

More than just a beautiful bloom, sunflowers yield seeds that, once pressed, create the perfect all-purpose oil. Rich in monounsaturated fats while boasting a smoke point of 460 degrees F, our Organic Sunflower Oil serves as an excellent alternative to olive oil for high heat cooking. It brings a light, delicate flavor to sauteed veggies and pan-fried dumplings alike.

By Guru July 27, 2023. Expeller pressing is a mechanical method for extracting oil from raw materials, such as seeds, nuts and algae. It is one of the most widely used methods in the oil industry, as it can produce high-quality oils with high efficiency and low cost. In this article, we will explain the expeller pressing technique, its

- Is expeller-pressed sunflower oil better than solvent extraction?

- While the solvent extraction method has a lower residual oil rate, it might entail a significant solvent consumption, resulting in elevated production costs for sunflower oil processing plants. Consequently, many oil production plants are inclined to opt for the method of expeller-pressed sunflower oil, achieving the desired production outcomes.

- Should sunflower oil extraction rate be increased?

- Increasing oil extraction rate of sunflower seeds is a critical concern for many sunflower oil processing businesses. A higher oil extraction rate translates to more profits and greater economic value for investors.

- What is a solvent extraction machine for sunflower oil?

- Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It’s worth noting that solvent extraction machine is costlier.

- Why is expeller pressed sunflower oil a good investment?

- The method of expeller-pressed sunflower seed oil is popular with investors due to its relatively lower investment costs and the adaptable scale of oil production it offers. This approach allows for the construction of both full-scale sunflower oil plant and small sunflower oil mills, making it more accessible to most investors.