monaco peanut oil processing equipment in cape town

- Usage: Peanut Oil

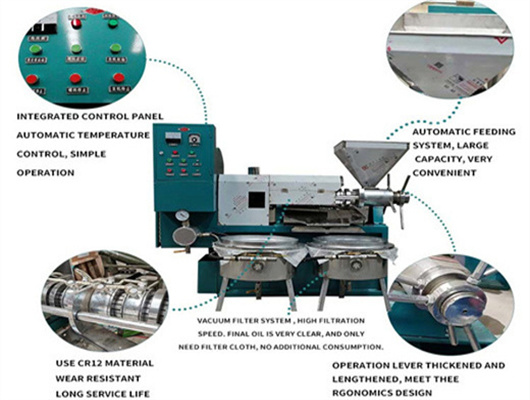

- Production Capacity: 80-800kg/h-99%

- Voltage: 110V/220V

- Dimension(L*W*H): 77*34*46(cm)

- Weight: 31.5 KG

- Core Components: Motor, Squeezer

- Oil type: Peanut Oil

- Keyword: S-10 model screw oil press machine cold oil expeller price

- Raw material: Peanut

- Function: Making Edible Oil

- Quality: Top Level

- Application: home use oil presser

- Selling point: Pure physical pressing, healthy nutrition

- Price: Factory price

- Character: Easy Movable

- Advantage: Simple Operation,High oil yield

- Machinery type: Automatic Micro Oil Mill Machine

- After Warranty Service: Video technical support, Online support

- Local Service Location: India, Colombia

Nut Processing Solutions

Gupfenstrasse 5. Uzwil. 9240. Switzerland. Contact us. Bühler has many years of experience in the industrial processing of nuts, such as hazelnuts, peanuts and almonds, covering complete solutions, individual machines and the latest automation technology.

LMC equipment is responsible for shelling 90 percent of the commercial peanut market. Our machines are designed specifically to maximize processing speed along with separation effectiveness. What makes LMC unique is the staff of peanut specialists that can design, build, deliver, and install an entire peanut processing operation. From cleaning

Akyurek Technology - Peanut & Groundnut Processing Equipment

Pre-Cleaning, Tempering Cylinder, Shelling, Separation, Grading/Sizing, Color Sorting, Blanching, Conveying Equipment, Buffer Bins, Efficient Dust Control System, Shell Hammer Milling, Automatization... Peanut processing and separation equipment is a long-term investment. Akyurek have provided after-sale service to our customers for over 40 years.

COMPANY PROFILE. We are a dedicated Company with new ideas, flexible to listen and understand the requirements of our Customers. We have developed our machines to suite the “HARSH” African environment. Our machines are “ROBUST”. The machines have been developed to be as “MAINTENANCE FREE” as possible. All our machines are

Groundnut Oil Manufacturing Process With Flowchart - Goyum

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the gravity/magnetic separation destoner, and grading.

Peanut Oil Processing Technology

Abstract. This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses

Peanut press machines, like those manufactured by Royal Duyvis Wiener, are the heart of peanut oil production. The process begins with raw materials, primarily peanut kernels. These are fed into the peanut press machine via a feed inlet, and the magic starts to happen. The machine applies pressure on the peanuts, resulting in oil being extracted.

- How much does peanut oil cost?

- In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization.

- What does Multotec do in Namibia?

- Selected staff have Namibian work permits and tend to customers needs in Namibia. Strategic stock of Multotec products are kept at the Cape Town branch for fast supply in the area. The industries that our Cape Town branch serves are mining/mineral processing, water treatment, food, brewery and petrochemical.

- How is peanut oil processed?

- Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization. The food uses of peanut oil and protein are reviewed in this article. This article reviews the production, processing, and food uses of peanut oil and protein.

- What is Multotec’s Western Cape branch?

- Multotec’s Western Cape branch represents and supports all of the products and services in the Multotec Group. They have a well equiped and established field service,especially competent in mill relining and screen maintenance. Supervisors and workers have necessary safety training and valid industrial medicals.