efficienttly peanut oil processing equipment in uganda

- Usage: crude cooking oil processing plant, crude cooking oil processing plant

- Type: crude cooking oil processing plant

- Production Capacity: 80kg/h, 500kg/h, 100kg/h

- Voltage: 220V/380V

- Power(W): according to the different capacity

- Dimension(L*W*H): 1200*400*900mm3

- Weight: according to the different capacity

- Certification: CE ISO, CE and ISO

- Material: carbon steel or stainless steel

- Capacity: 5-600T/D Peanut oil refinery

- Pakaging: according to customer's requirement

- Raw material: Peanut Seed

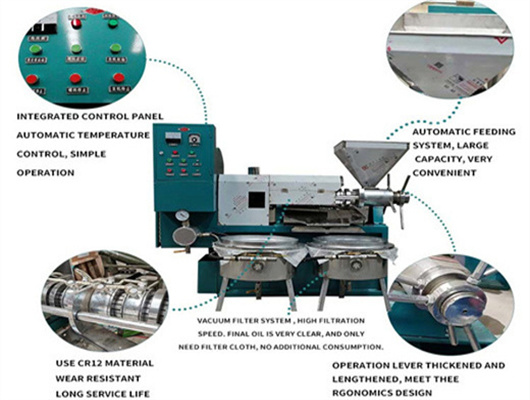

- Operation: easy operation and saving energy

- Warranty period: 1 year

- Delivery time: 1-2 months according to your capacity

- Feature: high quality refined oil

Groundnut Oil Manufacturing Process With Flowchart - Goyum

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization.

Explore the peanut press machine's role in oil yield | Duyvis

Peanut press machines, like those manufactured by Royal Duyvis Wiener, are the heart of peanut oil production. The process begins with raw materials, primarily peanut kernels. These are fed into the peanut press machine via a feed inlet, and the magic starts to happen. The machine applies pressure on the peanuts, resulting in oil being extracted.

PEANUT OIL PRESSING PROCESS. •Peanuts obtained from pre-treatment methods is subjected to pressing techniques to extract oil from peanuts. •The oil from the peanuts is extracted mainly by two pressing methods: -. High temperature pressing method. Cold pressing method.

Peanut processing [en] - CTCN

Peanut butter. The peanuts are first shelled and cleaned. They are then roasted at 425°F (218°C) for 40-60 minutes either a) on trays in an oven, the nuts being turned by hand from time to time or b) in equipment similar to that used for roasting coffee.

As shown in Fig. 3.4, during the process the temperature rises from 60 to 90°C, the oil/residual oil ratio of the system decreases gradually, reaching 4.5% at 90°C. . However, during the process of the temperature rise, the content of the soluble protein of the residual cake decreases slightly at 60–70°C, and when the temperature exceeds 70°C, the content of the soluble protein of the

A novel process for preparing low-fat peanuts: Optimization

An efficient defatting process of peanut seeds has been optimized using RSM. Many conventional methods of oil extraction (a) cause oilseed damage (cracking, grinding, or flaking), (b) leave solvent residues in the defatted peanuts and in the extracted oil, and (c) require high energy consumption.

Pre-Cleaning, Tempering Cylinder, Shelling, Separation, Grading/Sizing, Color Sorting, Blanching, Conveying Equipment, Buffer Bins, Efficient Dust Control System, Shell Hammer Milling, Automatization... Peanut processing and separation equipment is a long-term investment. Akyurek have provided after-sale service to our customers for over 40 years.