100-500tpd soybean seed oil line extractor in cape town

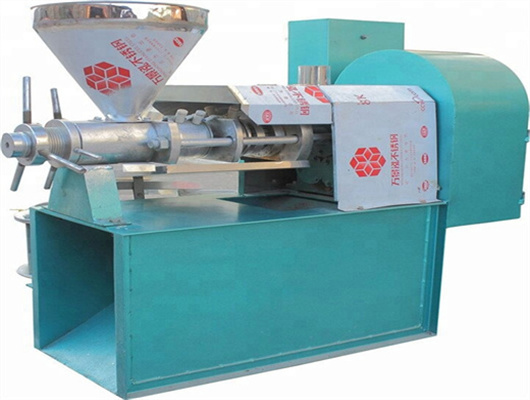

- Usage: small chia seed oil extraction machine

- Type: small chia seed oil extraction machine

- Production Capacity: 100 kg/h - 1000kg/h

- Voltage: 220V/380V/440V

- Power(W): 18.5KW/T

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- After-sales Service Provided: Overseas service center available

- Keywords: oil press machine

- Name: oil press

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business type: manufacturer

- Methods: Small chia seed oil extraction machine

- oil rate: 20%-98%

soybean oil extraction machine with 100-500tpd capacity

soybean oil extraction machine with 100-500tpd capacity. Usage: Soybean Oil, soybean solvent oil extraction plant; Type: soybean oil; Production Capacity: 100-500 Ton per day; Model Number: 1-200T/D; solvent material: n-hexane; residual oil in cake: 1%; extractor type: rotocel extractor; capacity: 20-500T/D

Soybean oil is a widely consumed vegetable oil derived from soybeans, one of the most important oilseed crops worldwide. It is known for its neutral flavor, versatile culinary applications, and nutritional benefits. Soybean oil is extracted from the seeds of the soybean plant through a process of mechanical pressing or solvent extraction.

Soybean oil bodies: A review on composition, properties, food

After standard aqueous extraction, the soybean oil bodies (SOBs) acquire a second protein layer consisting mainly of lipoxygenase, glycinin, β-conglycinin and Bd 30K/P34. As part of the construction of many food products, SOBs have been extensively studied to understand their properties and interactions with other components to replace the

Extract oil from various nuts and seeds; Oil extraction will vary (depending on feed raw material) Cape Town. Tel: +27 (0)21 447 3665; [email protected]; Johannesburg.

Characterization and Optimization of Soybean Oil from

Then, the request of response surface methodology to optimize oil extraction from soybean seed has been successfully confirmed at optimum parameters: temperature 70, solvent to solid ratio 10

First in oil with Alfa Laval. Reliable seed oil processing equipment covering all steps of refining for any type of edible seed oil. Oilseed processing solutions for boosting capacity, limiting loss and increasing yield, creating new profitable possibilities. Improved sustainability and reduced operational costs thanks to unique technologies

Desmet - Extraction

The seed, having been properly prepared, is separated into a crude oil fraction and a protein meal fraction by solvent extraction. The extractor utilizes a countercurrent, multi-stage washing with commercial hexane solvent to enable a reasonable quantity of solvent to extract a maximum quantity of oil.

major operations that are invo lved in the extraction of castor. oil by the old traditional method namely, collection of see d. pods, shelling of the pods/winnowing, boiling the seeds to. reduce

- How is soybean oil extracted?

- Yet, some operators overlook a critical step in their soybean oil extraction process to save significant time and energy. In solvent extraction, flaked soybeans are washed with hot solvent, typically hexane, to separate the solids from the fats. Multiple washes dissolve the oil and carry it away.

- What solvent is used in soybean extraction?

- In solvent extraction, flaked soybeans are washed with hot solvent, typically hexane, to separate the solids from the fats. Multiple washes dissolve the oil and carry it away. This oil solvent combination is also known as the miscella. The remaining material is the wet meal and solvent, also known as the marc.

- Should you use an expander to prepare oilseeds for extraction?

- Let¡¯s look at some of the benefits of using an expander to prepare oilseeds for extraction. The expander compresses the material, which allows for more capacity in the extractor. Specifically, the Solvex allows the extractor to accept 50% more soybean without any change in bed depth or residence time in the extractor.