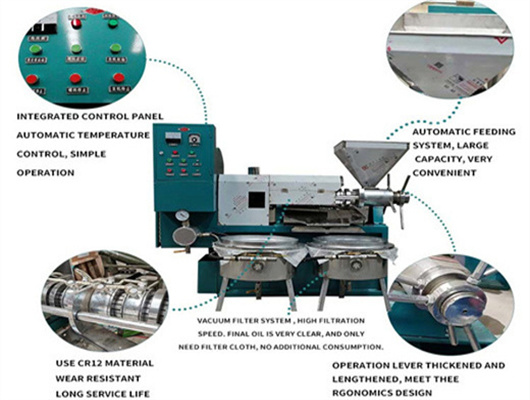

physical peanut oil refinery processing equipment in cameroon

Production, Processing, and Food Uses of Peanut Oilseed, Oil, and Protein - List - Major Reference Works - Wiley Online Library

Peanut oil is considered as a premium edible oil and commands a high price in both US and European markets. In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction.

Knowledge of these equipment items are essential for good refinery design, operation, and troubleshooting when necessary. The equipment described here falls into the following categories, and will be presented in the following parts: Part1 Vessels. Part 2 Pumps. Part 3 Compressors. Part 4 Heat Exchangers. Part5 Fired Heaters.

Processing and Food Uses of Peanut Oil and Protein

Peanuts are a relatively high-oil oilseed (with about 50% oil) and the meal after expelling contains about 6–7% oil. Generally the choice peanuts are used as confections (salted whole, in-shell). Lower grade peanuts are crushed for oil and meal. Peanuts like other crops are subject to contamination from aflatoxins.

Dingsheng Machine Offer Turnkey Edible oil refinery plant Projects, Peanut oil processing plant, Capacity: 30-3000TPD, professional technical service, contact us online. Dingsheng Machine is a leading manufacturer specializing in edible oil processing solutions and

Groundnut/ Peanut oil refinery plant

In general, there're 3 types of peanut oil refinery plant, batch type, semi-continuous and full-continuous. 1-2-3-5-10TPD batch type peanut oil refinery plant 10-15-20-25-30-50TPD semi-continuous peanut oil refinery plant 50-80-100-150-300-600-2000TPD full

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the gravity/magnetic separation destoner, and grading.

Effective physical refining for the mitigation of processing contaminants in palm oil at pilot scale

The control was a single physical refining to simulate a regular palm oil refining at full scale. A second, identical refining cycle was performed after the control treatment. Immediately after the control treatment, the oil was pumped back into the first tank (Tank X03) and was refined for the second time creating the T1 treatment.

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

- How is peanut oil processed?

- Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization. The food uses of peanut oil and protein are reviewed in this article. Abstract This article reviews the production, processing, and food uses of peanut oil and protein.

- Will Cameroon build a second oil refinery?

- Downstream: In September 2022, the government of Cameroon indicated it will launch a public tender to refurbish the national oil refinery SONARA. Due to the high level of refined petroleum imports, there have also been calls to build a second refinery. A second refinery would represent a significant business opportunity for U.S. firms.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- What is peanut pretreatment technology?

- Pretreatment Technology Peanut pretreatment refers to a series of treatment processes before oil production, such as cleaning, shelling, grading and selection, drying, cooling, thermal conditioning, pressing, and cooking.