sunflower oil expeller mill dimensions in sri lanka

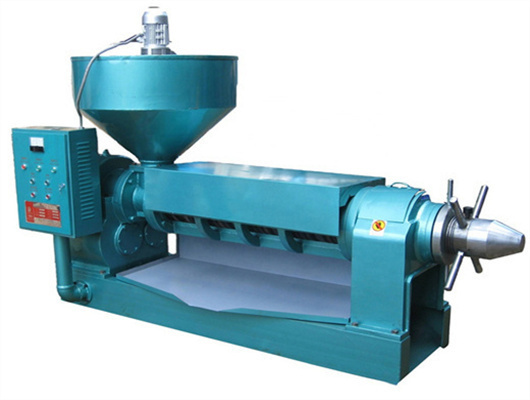

- Usage: Sunflower Oil

- Type: oil solvent extraction machinery

- Production Capacity: 10T-3000T/D

- Voltage: 380v/50Hz

- Power(W): 15 or 18.5k.w

- Dimension(L*W*H): 1360*950*1170mm

- Weight: up to specification

- Certification: ISO,SGS,BV

- Function: oil solvent extraction machinery

- Capacity Model: 10-5000TPD

- Suitable material: Sunflower and various oil cake

- Patent product: Yes

- Patent No.: ZL2007 20092291.7;

- Fully automatic: Yes

- Technology: Top technology in China

- Technology support: life time

- Warrenty: one year

- After-sale service: Offering installation and debugging

Products | Rex Industries

Table Top Oil Expeller—RL8. Virgin Coconut Oil Expeller - RL12. Oil Expeller Our clients currently from Sri Lanka, India, Indonesia, Tanzania, Philippines,

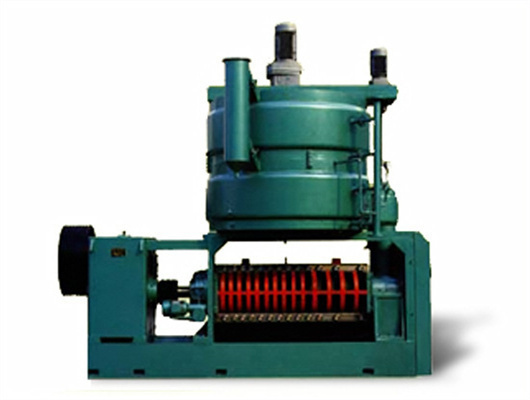

This Expeller has Two Chambers made of Cast Steel. Feed Side: Ø 16″ x 50″ Long, Discharge Side : Ø 16″ x 50″ Long. Hard Faced Worm Assembly, Discharge Ring. Main Worm Shaft can be withdrawn without disturbing the Gear Box. Chamber Lifting system is motorised. Kettle : 8 Stages with Steam Jackets of Ø 78”for efficient cooking of Seed.

Oil Expeller - Oil Mill Machinery - Edible Oil Plant Machinery

manufacturers & exporters of coconut, copra oil expellers, oil milling machinery, edible oil refinery, solvent extraction plant in Colombo, Sri Lanka +91 9780771062, +91 92163-00009 [email protected]

Since 1977, REX INDUSTRIES has been providing engineering services to Sri lanka & the worldwide. We thank all of our loyal customers who have made this milestone possible. Get In Touch. We are devoted in delivering our customers with high quality industrial machinery & spare parts by meeting international & legislative standards.

Sunflower Seeds Oil Expeller Machine Manufacturers and Exporters

Goyum is one of the leading manufacturer in sunflower seed oil processing line. We design complete sunflower oil plant, also we sell a large range of sunflower seeds oil expeller machines. Our objective is to manufacture and supply the most efficient sunflower oil extraction machines to our customers. We have been in the oil processing line

Sunflower Oil Mill Plant. We are a well-known manufacturer of small, medium and large scale industrial sunflower seed oil mill plants. Our oil mill machinery and equipment deserve praise for their excellent quality. The sunflower seed producing countries are Ukraine, Russia, Argentina, China, Romania, Bulgaria, Turkey, Hungary, USA and Tanzania.

sunflower seeds oil expeller zx18 and oil refinery plant in sri lanka

Congrats! Sinoder Group Signed Contract of 3T/D Coconut Oil Refinery Project with Sri Lanka Matugama Oil Mills (PVT) LTD Last August, we warmly welcomed the client from Sri Lanka to visit our company. The client from Sri Lanka Matugama Oil Mills (PVT) LTD want to built a 3t/d crude coconut oil reifnery plant in Sri Lanka. Get Price

Oil Expeller Spare Parts. Nitya Engineers are manufacturers & exporters of complete Oil Mill Plant Machinery Projects Installation in Colombo Sri Lanka. Our Plants caters to both small-scale and large-scale oil mill processing plants requirements. Vegetable Oil Plant, Edible Oil Plant, Mustard Oil Mill Plant, Canola Oil Plant, Rapeseed Oil

- What are the processes involved in sunflower oil mill plants?

- There are various processes involved in Sunflower Oil Mill Plants: Seed Cleaning, Seed Conditioning, Oil Extraction, Oil Filtration, Steam Generation and Oil Filling. Prior to extraction, oilseed is passed through the seeds cleaner to remove the impurities such as dust, leaves and metals.

- How are sunflower seeds conditioned?

- The sunflower seed contains 35 ¨C 40 % oil content and double pressing is required to extract maximum oil, 9 ¨C 11 % residual oil is left in the sunflower meal which is an excellent source of Animal Feed. The Sunflower Seeds are conditioned using Steam in a Vertical Cooking Kettle. The conditioned sunflower seeds are fed into the chamber.

- How to start a sunflower oil mill plant?

- Here we have listed some of the basic machinery required to Start a Sunflower Oil Mill Plant There are various processes involved in Sunflower Oil Mill Plants: Seed Cleaning, Seed Conditioning, Oil Extraction, Oil Filtration, Steam Generation and Oil Filling.

- Which countries produce sunflower seed oil?

- Our oil mill machinery and equipment deserve praise for their excellent quality. The sunflower seed producing countries are Ukraine, Russia, Argentina, China, Romania, Bulgaria, Turkey, Hungary, USA and Tanzania. We undertake turnkey project solutions for the complete Sesame Seed oil extraction plant.