peanut processing equipments canola oil processing in rwanda

- Usage: Peanut OIL, All kinds of oil seeds

- Type: sludge dewatering

- Production Capacity: 3~45m3/h

- Voltage: 220V/380V

- Dimension(L*W*H): 3605*1690*1600mm

- Weight: 1820kg

- Warranty: 3 years

- Core Components: Motor, PLC

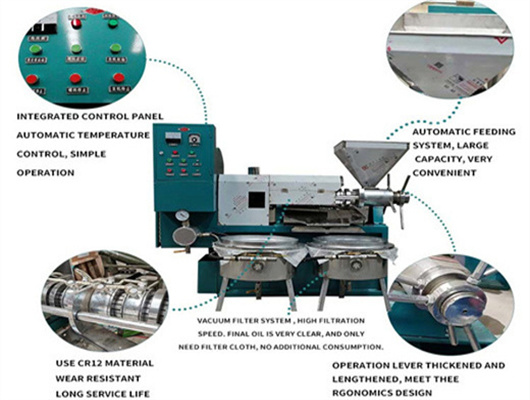

- Product name: screw oil press machine

- POWER: 1.95KW

- Treating Capacity: 3~45m3/h

- DS Standard Treating Capacity: 90-150kg/h

- Material: SS304

- Water Demand for Cleaning: 120L/h

- Net Weight: 1820kg

- Operating Weight: 281000kg

- Size: 3605*1690*1600mm

- After Warranty Service: Video technical support, Online support

- Local Service Location: Malaysia

- Certification: CE ISO

Peanut Processing Equipment

Peanut processing can result in salty peanuts, sweet peanuts, and other flavors. To do that, you soak or coat the peanuts raw or cooked in different solutions to allow the flavor to seep in. Salty or salted peanuts are soaked or cooked in a salty solution. Sweet peanuts are made by coating the peas in sugar or a sweetener like caramel.

Peanut butter. The peanuts are first shelled and cleaned. They are then roasted at 425°F (218°C) for 40-60 minutes either a) on trays in an oven, the nuts being turned by hand from time to time or b) in equipment similar to that used for roasting coffee.

peanut oil making equipment made in Rwanda

rwanda 1-200t peanut oil oil refinery plant. Peanut oil, also referred to as groundnut oil or arachis oil, is a vegetable-derived oil made from the edible seeds of the peanut plant.Though the peanut plant flowers above ground, the seeds or...

The new processing investments are aligned with the canola industry’s Keep it Coming 2025 strategic plan, that targets a growth in canola production and domestic processing volumes. Assuming processing capacity utilization of 90%, approximately 16 MMT of canola will be processed in Canada by 2025. This exceeds the industry’s target of 14

Groundnut Oil Mill Plant

Groundnut Oil Mill Plant Process. Groundnuts are also known as Peanut or Earthnut. The oil content in the peanuts is between 35% and 45% depending on the variety. Groundnut oil extraction involves several processes including groundnut decortication, cleaning, seed conditioning, crushing and filtration.

Canola Oil Extraction Plant Process. For processing Canola seed, the basic equipment we need are Seed Cleaner, Seed Cooker/Kettle, Oil Press, Filter Press, Steam Boiler, Screw Conveyors & Bucket Elevators. The following are steps involved in Canola Oil Extraction Plant: Step 1. Seed Cleaning. Canola Seeds are separated and cleaned to remove

Akyurek Technology - Peanut & Groundnut Processing Equipment

Pre-Cleaning, Tempering Cylinder, Shelling, Separation, Grading/Sizing, Color Sorting, Blanching, Conveying Equipment, Buffer Bins, Efficient Dust Control System, Shell Hammer Milling, Automatization... Peanut processing and separation equipment is a long-term investment. Akyurek have provided after-sale service to our customers for over 40 years.

Agroprocessing sector. Agro-processing in Rwanda is a flourishing sector that contributes up to a third of Rwanda’s GDP. This sector is a major source of employment and income, thus providing access to food and other necessities to large groups of the population. Rwanda has suitable agro-climatic conditions that allow the production of a

- How to extract canola oil?

- Canola Oil Pressing There are mainly two methods for extracting Canola oil, one is Mechanical Press and second is Solvent Extraction. In Mechanical Press, Canola oilseeds are pressed in a series of Screw Presses / Expellers. This process uses no chemical and leaves about 5-7% oil in the residual Cake/Meal.

- How is canola oil pressed?

- In Mechanical Press, Canola oilseeds are pressed in a series of Screw Presses / Expellers. This process uses no chemical and leaves about 5-7% oil in the residual Cake/Meal. This pressed cake can be subjected to Solvent Extraction for further Oil Extraction. Step 4. Solvent Extraction

- How to process canola seed?

- For processing Canola seed, the basic equipment we need are Seed Cleaner, Seed Cooker/Kettle, Oil Press, Filter Press, Steam Boiler, Screw Conveyors & Bucket Elevators. The following are steps involved in Canola Oil Extraction Plant: Step 1. Seed Cleaning Canola Seeds are separated and cleaned to remove impurities such as dust, metal, plant stalks.

- What is a screw pressing operation in a canola processing operation?

- A screw pressing operation has two major functions in a canola processing operation. First, it removes 60-70% of the oil from the canola flakes. Subsequent solvent extraction can then reduce the oil content to approximately 1 % in the extracted flakes.