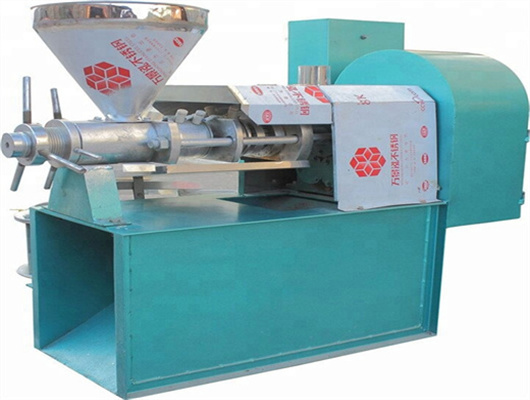

high extraction rate peanut oil extraction plant in rwanda

- Usage: Peanut seeds,Peanut processing machine

- Type: Peanut seeds,Peanutprocessing machine

- Production Capacity: 30kg-30t/day

- Voltage: 380V or designed by your needs

- Power(W): Depend on the machine you choose

- Dimension(L*W*H): Depend on the machine you choose

- Weight: Depend on the machine you choose

- Certification: CE and ISO

- Item: Peanut oil and Peanut oil refinery equipment for refining plant

- Supplier type: Manufacturer

- Manufacturing experience: 19 years

- Steel type: MiId steel and SS

- Raw materials: Peanut seeds,Peanut

- Fina product: Salad oil

- Processing method: Machanical press

- Handling capacity: according to custoemer design

- Model type: Continuous

- Main market: Africa, Aisa

Defatting and Defatted Peanuts: A Critical Review on Methods of Oil

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

The defatting ratio is the oil extraction yield, which is the ratio of extracted oil to the total oil that is initially present in peanut seeds before pressing. The mass of extracted oil is the difference between the initial oil content and the residual oil in the cake, which was determined by Soxhlet extraction (as shown in Section 2.6.1). 2.6.3.

Defatting and Defatted Peanuts: A Critical Review on Methods of Oil

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated

2 Chemical Composition and Bioactive Compounds of Extracts from Peanut Oil-Processing By-Products. The edible kernel comprised about 68–72% of the peanut, while the balance 28–32% is the peanut hull [ 8 ]. Peanut kernel’s average thickness, width, and length are 6.9 mm, 3.6 mm, and 8.5 mm, respectively [ 9 ].

Aqueous enzymatic extraction of peanut oil body and protein

Aqueous enzymatic extraction (AEE) is a new technology for extracting vegetable oil body which has the advantages of low energy consumption, product safety, mild reaction conditions, and simultaneous separation of oil and protein. Among the enzymes tested in the present work, Viscozyme L (compound plant hydrolase) exhibited the highest extraction activity during peanut oil extraction

Li et al. (2016) used a three-cylindrical roll crusher to improve oil and protein yields using the AEP of peanuts. The yield of free oil extracted from roasted peanut (150 °C, 20 min) using the AEP method was around 92.2% using the optimized processing conditions: solids-to-liquid ratio = 1:5; pH = 9; temperature = 60 °C, and time = 2 h [33].

Effects of Roasting Temperatures on Peanut Oil and Protein Yield

2.2. Aqueous Enzymatic Extraction of Peanut Oil and Protein Peanut oil and protein were prepared using the methods described by Liu [18] and Zhao et al. [19] with minor modiÞ cations. Figure 1 presents a ß owchart of the AEE for peanut oil and protein. For the de-red-coating treatment, the peanuts were roasted in an

Oil body emulsions (OBEs) affect the final oil yield as an intermediate in the concurrent peanut oil and protein extraction process using an aqueous enzyme extraction (AEE) method. Roasting temperature promotes peanut cell structure breakdown, affecting OBE composition and stability and improving peanut oil and protein extraction rates. Therefore, this study aimed to investigate the effects of

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- How is peanut oil extracted?

- Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent ( n -hexane) extraction [ 29 ]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

- Is oil extraction from peanuts environmentally friendly and cost-efficient?

- A comparison in terms of productivity, efficacy, specificity, quality of the extracts, and operating conditions was conducted, which favored the novel methods as being mostly environmentally friendly and cost-efficient. Chemical methods of oil extraction from peanuts.