good service peanut oil processing equipment in rwanda

- Usage: Peanut Oil

- Type: Peanut Oil Extraction Machine

- Production Capacity: 15-16ton/24hrs for oil seeds

- Voltage: 380V or 220V

- Dimension(L*W*H): 2200x850x1560mm

- Weight: 1400kg

- Core Components: Motor, Pressure vessel, Gear, Bearing, Engine, Gearbox

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Certification: CE,ISO,SGS

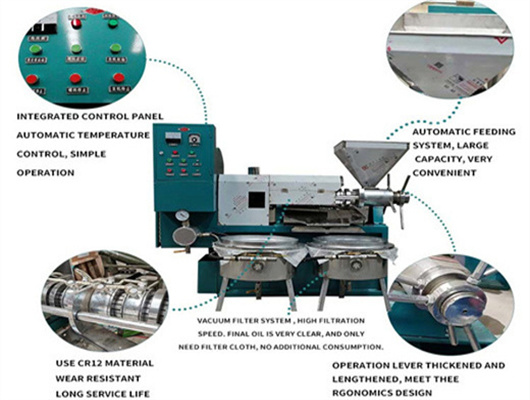

- Name: 6YL-160 Oil Press

- Application: oil press machine

- Capacity: 15-16ton/24h oil press

- Main power: 22-30kw

- oil residue in cake: less than 7%

- Matching machines: roaster,filter machine,conveyor etc

- Company type: factory and manufacture

- Advantage: Energy Saving more effect

Advanced nut processing with the peanut oil press machine

It’s a business production powerhouse that does more than just squeeze oil out of peanuts. It streamlines the entire process and results in a high-quality, accurate product The automatic peanut oil Press is a popular model. It’s renowned for its efficiency, able to process 18-20 Kg/Hr. Explore our nuts & seeds processing equipment.

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the gravity/magnetic separation destoner, and grading.

Boost yield in peanut oil with optimal processing

Step 4: Refining. Crude peanut oil refining is a comprehensive process, which includes the removal of impurities and a decrease in AV acid. The refined oil then undergoes a crossover challenge study, giving us the final edible peanut oil. This product is popular due to its high content of linoleic acid, palmitic acid, and omega-6 fatty acids.

This can be done and allowing extra time for an adequate output from the cake and the oil. 3. Pressing peanut oil. After frying, the peanuts can enter the oil press for pressing. When pressing, pay attention not to feed too fast, and feed slowly. If the feed is too fast, the pusher wire will be squeezed out.

Peanut Processing Equipment

Peanuts, also known as groundnuts are one of the most popular edible seeds in the world. You can eat them as-is or process them further into on-the-shelf products like peanut butter, oil, snacks, and soups. Depending on what you want to make, some peanut manufacturing processes include roasting, frying, boiling, grinding, pressing, and coating

The production capacity of peanut oil machines is as diverse as the businesses they serve. Sizes and capacities range from 10-12 Kg/Hr to machines capable of outputting 100-200 Kg/Day power. For larger-scale operations, machines with a 20-60 Ton/Day operation type are available. These 18-20 Kg/Hr machine type variants are perfect for businesses

Peanut Oil Processing Technology

It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment.

Pre-Cleaning, Tempering Cylinder, Shelling, Separation, Grading/Sizing, Color Sorting, Blanching, Conveying Equipment, Buffer Bins, Efficient Dust Control System, Shell Hammer Milling, Automatization... Peanut processing and separation equipment is a long-term investment. Akyurek have provided after-sale service to our customers for over 40