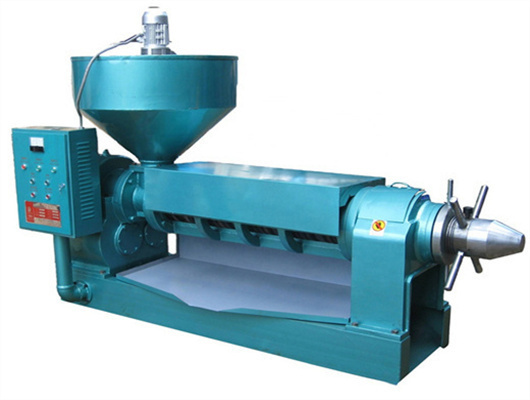

ce certificated sunflower seed oil expeller most in rwanda

- Usage: small Sunflower oil refinery

- Type: small Sunflower oil refinery

- Production Capacity: 10-70T/D

- Voltage: 220v-380-415v

- Power(W): according to capacity

- Dimension(L*W*H): 1610x615x1260mm

- Weight: different according to capacity

- Certification: ISO/CE/ ISO9000

- Steel type: SS 304 and part of carbon steel

- Oil standard: 1st grade edible oil

- Adapt to: all kinds of vegetable oil materials

- phospholipid: according to standard requirement

- Guarantee period: 1year

- Process capacity: factory

- Method: small Sunflower oil refinery

- process: deodorization

- company strength: more than 30years experiences

- Acid impurity: according to standard requirement

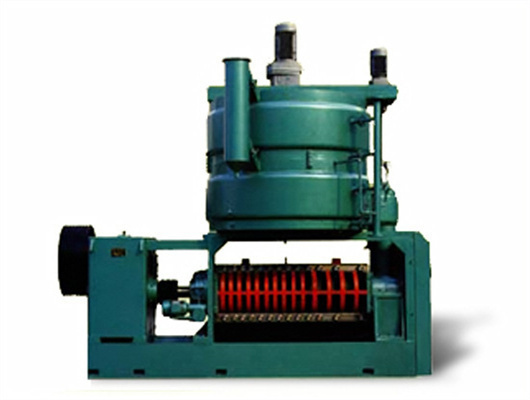

Expeller Pressed Sunflower Oil vs Solvent Extraction Methods

Production Process for Sunflower Seed Oil. Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%.

Abstract. An expelling machine was developed for extracting oil from decorticated sunflower seeds. The expelling unit consists of an auger with decreasing pitches and the heating of seeds is

Development of a Sunflower Oil Expeller - Cornell University

The seeds of sunflower are rich in oil (about 50 wt. %) and it is considered to be a potential source of proteins for human consumption. This is due to its high ratio of polyunsaturated/saturated fatty acids and the high content in linoleic acid (Ohlson, 1992; Isobe et al., 1992). The oil extracted from sunflower seeds is a good source of

Ingredient: 100% unrefined organic sunflower seed oil, expeller pressed without added heat and gently filtered. Good Food Award winner for best sunflower seed oil; Unlike most vegetable oils in the grocery store, no harsh chemical or thermal refining is used in in our oil production. Flavor profile: mild flavor of fresh sunflower seeds

Development and Performance Evaluation of an Optimized Screw type

untreated and raw sunflower seed. Singh and Bargale (2000) designed and developed a modified oil expeller based on a novel principle of single feed, double stage compression to improve the efficiency of oil recovery. Bamgboye and Adejumo (2008) also developed and modified a screw press for sunflower oil expeller. Modh and Mevada (2011)

Goyum is one of the leading manufacturer in sunflower seed oil processing line. We design complete sunflower oil plant, also we sell a large range of sunflower seeds oil expeller machines. Our objective is to manufacture and supply the most efficient sunflower oil extraction machines to our customers. We have been in the oil processing line

Development of a Sunflower Oil Expeller | Semantic Scholar

An expelling machine was developed for extracting oil from decorticated sunflower seeds. The expelling unit consists of an auger with decreasing pitches and the heating of seeds is achieved by generated steam, which heats the surrounding of seeds passage. The machine was tested at auger speeds of 30, 40, 50rpm respectively and three throughputs. Results showed that performance efficiencies

The Pressing Section of the Mini Oil Mill. Pressing is one of the most important processes in the whole oil mill plant. After a series pretreatment for oilseeds, the raw material could be sent to the pressing workshop to extract oil from seeds and nuts. The mini oil mill usually connects a serious oil mill machinery and equipment such as screw

- Which countries export sunflower-seed or safflower oil?

- Trade in Sunflower-seed or safflower oil, crude represent 0.061% of total world trade. Sunflower-seed or safflower oil, crude are a part of Seed Oils. Exports In 2022 the top exporters of Sunflower-seed or safflower oil, crude were Ukraine ($4.7B), Russia ($2.63B), Bulgaria ($1.34B), Argentina ($1.27B), and Turkey ($707M).

- What is a solvent extraction machine for sunflower oil?

- Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It’s worth noting that solvent extraction machine is costlier.

- Why is expeller pressed sunflower oil a good investment?

- The method of expeller-pressed sunflower seed oil is popular with investors due to its relatively lower investment costs and the adaptable scale of oil production it offers. This approach allows for the construction of both full-scale sunflower oil plant and small sunflower oil mills, making it more accessible to most investors.

- Is expeller-pressed sunflower oil better than solvent extraction?

- While the solvent extraction method has a lower residual oil rate, it might entail a significant solvent consumption, resulting in elevated production costs for sunflower oil processing plants. Consequently, many oil production plants are inclined to opt for the method of expeller-pressed sunflower oil, achieving the desired production outcomes.