big sunflower oil expeller luxembourg in pakistan

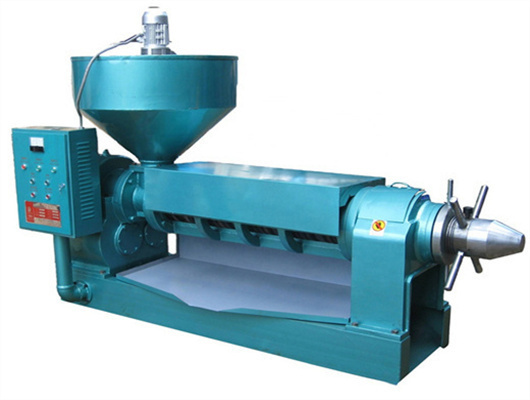

- Model Number:YZYX120WZ

- Type: Spiral Sunfower Oil Press

- Application: Cooking Oil

- Voltage: 380V

- Appearance: Uniaxial

- Press Materials: Sunflower

- Press Series: Second

- Product Name: Sunflower Oil Press with Good After-Sale Services

- After-Sales Service Provided: Engineers to Service Machinery Overseas

- Wearing Parts: Squeeze Bars, Squeeze Spiral and Loop

- Port: Shanghai, Chongqing, Guangzhou, etc

- Delivery Time: 7~30days Once Order Confirmed

- Advantages: High Capacity, Easy Operation

- Color: Any Color You Like

- Automatic Grade: Semi-Automatic

- Transport Package: Wooden Box

- Specification: certificated: ISO, BV, SGS

- Production Capacity: 400pieces/Month

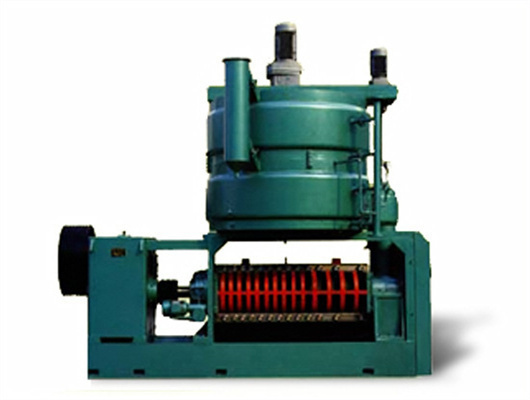

Large Capacity Oil Processing Machine

This Expeller has Two Chambers made of Cast Steel. Feed Side: Ø 16″ x 50″ Long, Discharge Side : Ø 16″ x 50″ Long. Hard Faced Worm Assembly, Discharge Ring. Main Worm Shaft can be withdrawn without disturbing the Gear Box. Chamber Lifting system is motorised. Kettle : 8 Stages with Steam Jackets of Ø 78”for efficient cooking of Seed.

Here we can give your some references on equipment cost of sunflower cooking oil production line: The cost of 5ton/day oil pressing line is about $5500. The cost of 1ton/day oil refinery plant is about $19800. For 1ton/day sunflower oil dewaxing machine, the price is about $13000.

Expeller Pressed Sunflower Oil vs Solvent Extraction Methods

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier.

Expeller pressing is the mechanical method for extracting oil from seeds and nuts. It involves crushing the raw material, such as soybeans, sunflower seeds, or olives using a mechanical press without the use of chemicals or excessive heat. Cold-pressed oils are extracted using a similar mechanical process as expeller pressing, but the raw

Sunflower Oil Production Process Introduction - Edible Oil

The processing characteristics of first-grade sunflower oil are: First of all, sunflower seeds are selected and cleaned to remove impurities, and then the seeds are de-husked and crushed. After that the embryo is flaked and steamed in the frying pan, the fried product is pre-squeezed out of the oil and the remaining oil is extracted by solvent

GOYUM 1500. 45 – 150 Tonnes per 24 Hours. 3-Phase 170 H.P. 5500 MM. 1380 MM. 1980 MM. Are you looking for the most suitable and cost effective sunflower seed oil expeller or sunflower seed oil mill plant to start your own sunflower seed oil manufacturing business, then you are in the right place. GOYUM is the best and reliable manufacturer

Oil Expeller in Pakistan, Free classifieds in Pakistan - OLX

Find the best Oil Expeller in Pakistan. OLX Pakistan offers online local classified ads for Oil Expeller. Post your classified ad for free in various categories like mobiles, tablets, cars, bikes, laptops, electronics, birds, houses, furniture, clothes, dresses for sale in Pakistan.

The most suitable temperature for the growth of sunflower seed is 20 – 27°C with abundant water. There are several varieties of seeds available consisting of 36% of Oil to 40% of oil based on cultivated area soil condition and species of the seed. The Oil extracted from sunflower seeds either by screw press or by solvent extraction process.

- What is sunflower seed oil?

- Sunflower seed oil is the most ancient seed of North America which was cultivated during 3000 BC as per available records and it moved to Russia and from there to other countries. The most suitable temperature for the growth of sunflower seed is 20 ¨C 27°C with abundant water.

- How to extract oil from sunflower seeds?

- The Oil extracted from sunflower seeds either by screw press or by solvent extraction process. The Seeds will be either de hulled or whole seed extraction is taking place based on the requirement of the protein content of the De oiled Meal. Preparation of Sunflower Seed for Solvent Extraction Process:

- How to remove hulls from sunflower seed?

- The Sunflower seed 20% to 27% of hulls which will be removed with the help of Crackers and aspiration separations process called dehulling. The sunflower seed passed through the dehullers will remove upto 15% to 20% of the hulls.