bath type peanut oil refined processing equipment in nigeria

Groundnut Oil Manufacturing Process With Flowchart - Goyum

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Large percentage of palm kernel oil in Nigeria market is processed from the traditional method which is not only unhygienic but is equally labourious and time consuming. This research work is focused on the design and construction of a palm kernel oil extraction machine. The machine was designed and fabricated using locally available materials.

Refining in Nigeria: history, challenges and prospects

There are four major existing refineries as follows: Old Port Harcourt Refinery; capacity 60,000 bpsd commissioned in 1965. Warri Refining and Petrochemical Company; capacity 125,000 bpsd commissioned in 1978. Kaduna Refining and Petrochemical Company; capacity 110,000 bpsd commissioned in 1980. New Port Harcourt Refinery; capacity 150,000 bpsd commissioned in 1989. Thus, the total installed

Palm oil, which is extracted from the fleshy mesocarp of the palm fruit, has been a vital resource in the majority of Nigerians diet. The global need for palm oil is fast increasing because it serves as a source of income. After been refined, the oil is filtered to get a liquid fraction, which is being utilized as cooking oil.

Palm and Palm Kernel Oil Production and Processing in Nigeria

The Nigerian vegetable oil market uniquely features palm kernel oil packaged for household and commercial food frying. More than 60% of refineries in Nigeria are built on palm kernel oil as raw materials. This is because processing of palm kernel oil involves degumming, bleaching, deodorization, cooling, and packaging.

mostly use complete fractiona l process (85%) in refinin g pa lm kernel oil. About 10% use zero refining. method while 5% of the proc essors use incomplete fractiona l process. Plastic cont a

Chemical vs. Enzymatic Refining to Produce Peanut Oil for Edible Use

Regarding the toxicity towards S. zeamais, the crude peanut oil and the chemically refined peanut oil had lower LC50 values (1.836 and 1.372 g kg−1, respectively) than the oils rectified through enzymatic degumming (LC50 from 2.453 to 4.076 g kg−1), and, therefore, they can be suggested as sustainable stored grain protectants.

C.G Okeke and S.L Oluka (2017) Review of Palm kernel oil processing and storage Techniques in South East Nigeria. Journal of Experimental Research Vol. 5 p 1 -2 Pailm oil Processing Technology

- Which processing method is used in peanut oil production?

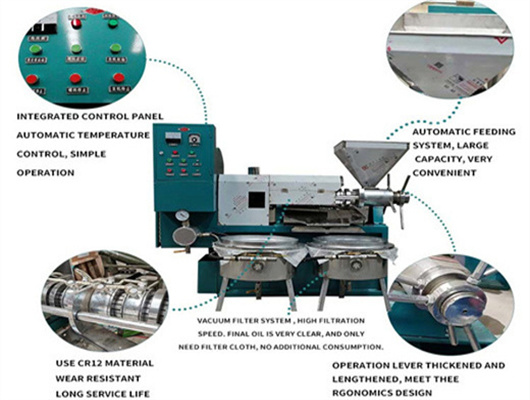

- Because of the high oil content, two types of the processing technology can both used in peanut oil production: pressing method and solvent extraction method. Which method used depends on your requirement and the capacity you want. Henan Doing Company supplies the peanut oil processing plant with the input capacity from 10tons/day to 2000tons/day.

- When was the first BP refinery built in Nigeria?

- It embarked on a project to build the first refinery in the country near Port Harcourt. The 38,000 barrels per day (bpsd) Shell-BP Refinery was completed and commissioned in 1965. It was a simple hydro-skimming plant. The Federal Government of Nigeria acquired 50% shareholding under a participatory agreement with Shell-BP.

- What is a peanut oil processing factory?

- The whole peanut oil processing factory includes pretreatment plant, solvent extraction plant and refinery plant. The processing steps of peanut pretreatment and oil pressing workshop: Shelling- separating shells and kernels- cleaning- crushing- flaking- cooking- oil pressing or pre-pressing.

- What is the output capacity of Henan doing company peanut oil processing plant?

- Henan Doing Company supplies the peanut oil processing plant with the input capacity from 10tons/day to 2000tons/day. The whole peanut oil processing factory includes pretreatment plant, solvent extraction plant and refinery plant.