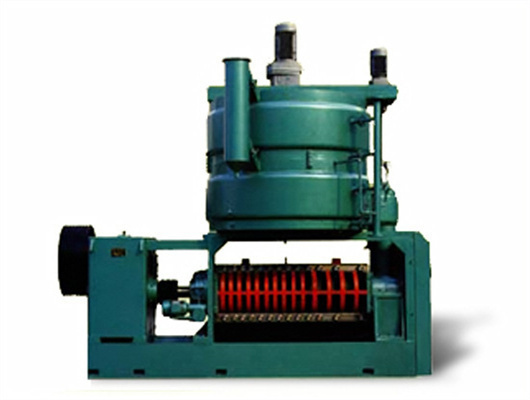

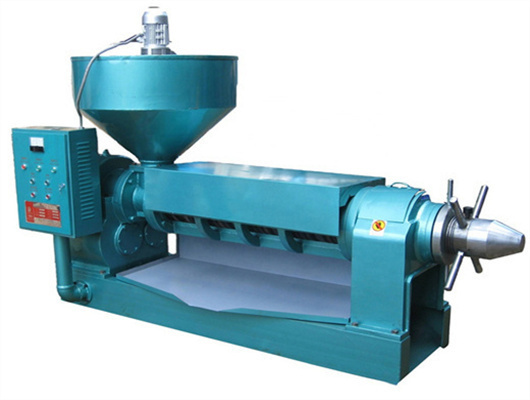

hot sunflower oil expeller has a high oil rate in mozambique

- Usage: Sunflower OIL, Cooking Oil

- Type: Sunflower Oil Extraction Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V

- Dimension(L*W*H): Depend on Capacity

- Weight: 230 KG, 230KG-250KG

- Core Components: Motor, Pressure vessel, Pump, Gear, Bearing, Engine, Gearbox

- Oil type: Sunflower Oil

- Name: sunflower oil press Machine

- Raw material: Sunflower, soyabean, Sunflower

- Material: Stainless Steel 304

- Certification: ISO9001,CE,BV

- Power(W): 5.5/7.5

- Function: Oil Press + Drum Filter,Making Edible Oil

- Capacity: 80-200kg/h

- Feature: High Efficiency Low Cost

- After Warranty Service: Video technical support

Expanding and Expelling - AOCS

Expanding and Expelling. Home Edible Oil Processing. Although mechanically the machines used to perform the expanding and the expelling functions share a number of common features, they serve completely different purposes. The expander is a unit assigned to seed or product preparation, whereas the expeller is the machine for mechanical oil

Expeller pressing is the mechanical method for extracting oil from seeds and nuts. It involves crushing the raw material, such as soybeans, sunflower seeds, or olives using a mechanical press without the use of chemicals or excessive heat. Cold-pressed oils are extracted using a similar mechanical process as expeller pressing, but the raw

High Oleic Sunflower Oil Vs Expeller Pressed: The Ultimate Showdown Of

The Verdict. Both high oleic sunflower oil and expeller pressed oil are healthy and versatile cooking oils. High oleic sunflower oil is ideal for high-heat cooking, while expeller pressed oil is better suited for medium-heat cooking. Ultimately, the best choice for you depends on your cooking style and preferences.

By Guru July 27, 2023. Expeller pressing is a mechanical method for extracting oil from raw materials, such as seeds, nuts and algae. It is one of the most widely used methods in the oil industry, as it can produce high-quality oils with high efficiency and low cost. In this article, we will explain the expeller pressing technique, its

Sunflower Oil Production Process Introduction - Edible Oil Expeller

De-shelled pressing-leaching technology is the key point of sunflower oil production line which avoids the negative impact of over-refining, high temperature, and acid and alkali effects on oils, so that the nutrients in the oil can be well preserved. For example, the content of vitamin E in de-shelled squeezed sunflower oil is 75.5mg/100g.

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier.

What is expeller pressed sunflower oil? Good or bad?

Expeller pressed sunflower oil. First of all, if you see that term “expeller-pressed” on the label of sunflower oil, it means it’s a good oil and worth to buy. Expeller-pressed is a method to make sunflower oil, which means sunflower oil is squeezed out of sunflower seeds only through physical extrusion method, and then remove some

Applying heavy pressure to olives or seeds until oil starts seeping out. An expeller is a big screw that is tightened until it crushes the nut/seed and causes the oil to run. This method provides yields of only 65-70% of the oil. Many companies then try to extract the rest of the oil using the chemical solvent.

- What is a solvent extraction machine for sunflower oil?

- Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It’s worth noting that solvent extraction machine is costlier.

- What are the two methods of sunflower oil extraction?

- Common sunflower seed oil extraction processes can be categorized into two methods: expeller pressed sunflower oil and solvent extraction. Next, we will briefly introduce these two methods of sunflower oil production. Sunflower Oil Press & Extraction Machinery for Sale What is expeller pressed sunflower oil?

- Is expeller-pressed sunflower oil better than solvent extraction?

- While the solvent extraction method has a lower residual oil rate, it might entail a significant solvent consumption, resulting in elevated production costs for sunflower oil processing plants. Consequently, many oil production plants are inclined to opt for the method of expeller-pressed sunflower oil, achieving the desired production outcomes.

- Why is expeller pressed sunflower oil a good investment?

- The method of expeller-pressed sunflower seed oil is popular with investors due to its relatively lower investment costs and the adaptable scale of oil production it offers. This approach allows for the construction of both full-scale sunflower oil plant and small sunflower oil mills, making it more accessible to most investors.