sunflower oil refining production machine in malaysia

- Usage: refiner machine

- Type: refiner machine

- Automatic Grade: Automatic

- Production Capacity: 50TPD~200TPD

- Model Number: Q-0705

- Voltage: addcording to capacity

- Power(W): addcording to capacity

- Weight: addcording to capacity

- Certification: ISO9001

- steam consumption: 450kg/T oil

- phosphoric acid: 2~3kg/T oil

- Bleaching earth consumption: 5~50Kg/T oil

- Deodorization loss consumption: ≤0.5%

- Waste bleaching earth oil content: <35%

- description: semi-continuous

- business type: manufacturer

- usage: oil refining

- material: Stainless steel & carbon black

Oils Fats Refining Equipment and Turnkey Plants

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

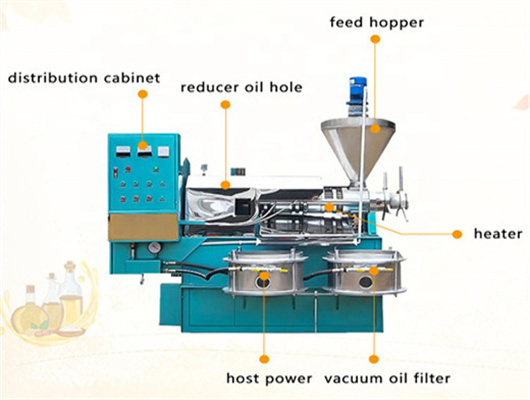

The oil is extracted directly from the sunflower seeds by a screw type oil press machine. Sunflower seeds are cold-pressed (or hot pressed) at a certain temperatures, and the protein-rich cake that remains after the seeds are processed into oil is used as animal feed, retaining 99% of the nutrients in sunflower oil without the use of chemical solvents.

Sunflower oil refining machine from crude oil to first grade

An industrial sunflower oil refining machine (edible oil refinery machine) is developed to meet the needs of various edible oil processing plants to refine sunflower seed oil and other kinds of cooking oil. Such equipment can produce fourth-grade oil, third-grade oil, second-grade oil, and first-grade oil. An industrial sunflower oil refining

In this article, we will discuss the complete sunflower oil production process in detail. Step 1: Cleaning and Shelling. The sunflower seeds are first cleaned and shelled in an oil mill. This process involves removing any impurities and outer shells from the seeds. Step 2: Cracking.

PACOIL : Pacific Oils & Fats Industries

Pacific Oils & Fats Industries Sdn Bhd (Pacoil) was established in year 2002 and is one of the largest edible oil refineries located in the southern part of Malaysia. PACOIL systems are certified by Jakim Halal, MSPO, ISO9001, ISO14001, HACCP, RSPO, ISCC & KOSHER. Our main revenues come from Bulk Oil, FMCG Packaging, Tank Rentals to 3rd parties

Production of Refined Sunflower Oil in Malaysia. Discover production data of Refined Sunflower Oil in Malaysia. Get production volume, price data, trends, and more. The information below is based on the FAO code 0268 (Oil, sunflower).

PHYSICAL REFINING OF SUNFLOWER OIL

Sunflower oil has a high nutritional value, having 62-70% linoleic acid content (essential fatty acid) but on the other hand this high polyunsaturated fatty acid content makes this oil sensitive to oxidation. Crude sunflower oil, which has reached a certain level of oxidation is difficult to refine. There are two main difficulties: 1.

The steps involved in Sunflower Oil Refining Process: Degumming. Neutralization. Water Washing. Vacuum Drying. Bleaching. De-waxing. Deodorisation. The chemical refining stages of Sunflower oil are also similar to other soft oils except dewaxing which is additional as sunflower oil contains wax which will be removed by dewaxing process.