sunflower seed oil production refineing machine in zimbabwe

- Usage: Edible Oil

- Type: Edible Oil Refinery Machine

- Automatic Grade: Automatic

- Production Capacity: 100-200TPD

- Model Number: DT-200

- Voltage: 220V/380V/415V

- Power(W): 1-30kw

- Certification: ISO9001

- Feature: Multifunction High efficient

- Warranty: 1year

- Advantage: Energy Saving and environment protection

- Material: Part of are stainless steel

- Residual: less than 2%

- Supplier strength: with 30 years experiences

- Machine color: According customer need

- Suitable objects: sunflower seed peanut repe seed

- Whole production line: pressing, solvent extraction, refining

- Business type: Manufacturer

Extracting and refining steps of sunflower oil.

Sunflower seed oil is used for making cooking oil, salad oil, margarine, and shortening. The oil has a light-yellow color and a distinct smell, which can be eliminated through deodorization [72] .

Sunflower oil contains phosphatides like other oils 0.5% to 1.5% based species and variety of the seed. This will be removed through the standard degumming process by addition 2% water and 1kg to 1.5Kg of food-grade phosphoric acid to the oil at 60°C and allowing to mix for 20 minutes and then by separating through the centrifugal separators.

Sunflower Seed Preparation and Oil Extraction

Sunflower seed processing focuses on sunflower oil as the most valuable product. It is used as high-value oil in various food applications. The deoiled meal is considered a byproduct and is mostly used as animal feed. In 2011, annual world production of deoiled sunflower meal was at 16 million tons (FAO, 2013).

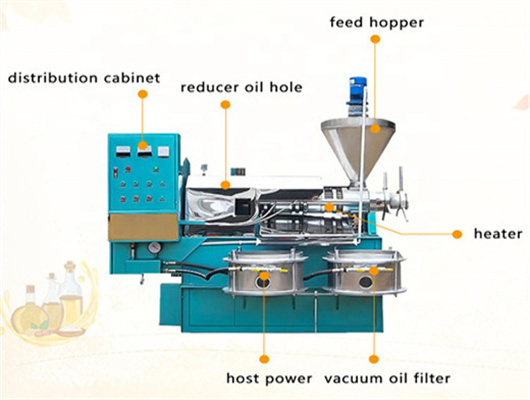

An industrial sunflower oil refining machine (edible oil refinery machine) is developed to meet the needs of various edible oil processing plants to refine sunflower seed oil and other kinds of cooking oil. Such equipment can produce fourth-grade oil, third-grade oil, second-grade oil, and first-grade oil. An industrial sunflower oil refining

Sunflower Oil Extraction Process, Methods – A Full Guide

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning.

Evolution of sunflower seed world production (Million Tons, yellow bars) and acreage (Million ha, red bars) 1976-2018 (Source: Oil World, 2019). Evolution of oilseeds production 1975-2019.

Sunflower Seed Oil Refining Machine

According to different raw materials, the process of Sunflower oil refining includes mechanical refining method, chemical refining method and physical refining process refining process. +86-371-86159555

Sunflower seed oil production does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. 6 Processes of Sunflower Oil Production