high oil production sunfloweroil refiner machine in lesotho

- Usage: biodiesel refining

- Type: Edible Oil Refinery Machine

- Automatic Grade: Automatic

- Production Capacity: 45 sets per year

- Voltage: 380V/440V

- Power(W): 30KW

- Dimension(L*W*H): 1200*2800*1200mm

- Weight: 500TON

- Certification: CE/ISO9001/BV

- usage: biodiesel refining

- oil clolor: yellow

- advantage: save energy

- bleaching earth consumption: 5-50kg/t oil

- decolor function: remove the bad color

- deodor function: remove the bad smell

- Name: biodiesel refining

- Application: Oil Production Line

- Color: Customers' Request

- Function: Making Edible Oil

high productivity sunflower oil production plant in lesotho

Pretreatment Workshop of complete sunflower oil extraction machine Craft flow: Crude seeds→ cleaning → softening → ex panding → drying → to extraction workshop Pretreatment and prepressing section is a very important section before&nb sp;extraction.It will directly affect extraction effect.

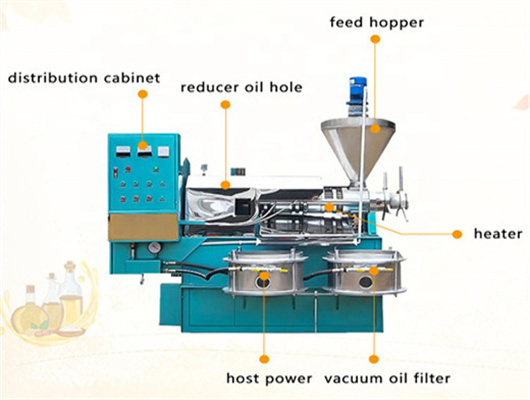

The oil is extracted directly from the sunflower seeds by a screw type oil press machine. Sunflower seeds are cold-pressed (or hot pressed) at a certain temperatures, and the protein-rich cake that remains after the seeds are processed into oil is used as animal feed, retaining 99% of the nutrients in sunflower oil without the use of chemical solvents.

Sunflower Oil Refinery Plant Process

The steps involved in Sunflower Oil Refining Process: Degumming. Neutralization. Water Washing. Vacuum Drying. Bleaching. De-waxing. Deodorisation. The chemical refining stages of Sunflower oil are also similar to other soft oils except dewaxing which is additional as sunflower oil contains wax which will be removed by dewaxing process.

De-shelled pressing-leaching technology is the key point of sunflower oil production line which avoids the negative impact of over-refining, high temperature, and acid and alkali effects on oils, so that the nutrients in the oil can be well preserved. For example, the content of vitamin E in de-shelled squeezed sunflower oil is 75.5mg/100g.

Full set of sunflower oil production plant with high oil

The processing steps of the sunflower oil production line mainly include roasting, pressing, filtering, refining and filling. The production line has a high degree of automation, various outputs, and high oil quality. The sunflower oil processing machine is suitable for small and medium-sized oil extraction factories or workshops.

Sunflower Oil Extraction Machine_Cooking oil production. Sunflower Oil Extraction Machine. Time Online:2017-06-13 15:39. Product Description: Golden sunflower seed oil, refreshing texture, it contains vitamins A, B, D and E, and rich in unsaturated fatty acids.

Lesotho Sunflower Seed Oil Production Line

About Lesotho sunflower seed oil production line is an essential process for a complete Biodiesel Oil Production Line because Biodiesel production line adopts high efficiency biodiesel technology at high temperature to obtain biological diesel oil as renewable source. This environmental protective and reproductive biodiesel is available under certain temperature, pressure, catalyst, and form

Such equipment can produce fourth-grade oil, third-grade oil, second-grade oil, and first-grade oil. The daily processing capacity of the sunflower oil refinery machine reaches 100 kg to 10 tons or more. The sunflower oil refinery machines can be divided into intermittent and continuous types to meet the needs of different users.