in soybean oil productline oil refing process in lagos

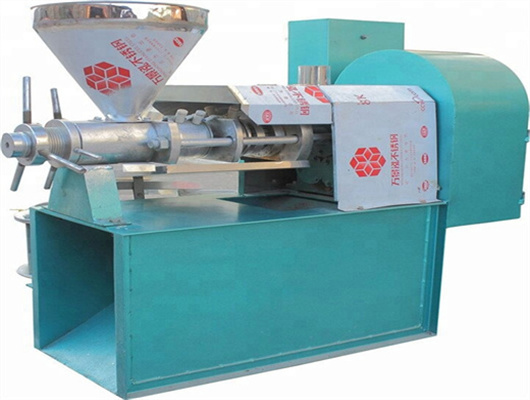

- Usage: oil refining machine

- Type: Edible Oil Refinery Machine

- Automatic Grade: Automatic

- Production Capacity: 100%

- Model Number: HT-RBOM

- Voltage: 380V

- Power(W): 95kw

- Dimension(L*W*H): according to the specification

- Weight: 35ton

- Certification: ISO9001,BV,CE

- Oil quality: Grade 1

- Materials: Carbon steel Q235 and stainless steel SS304/316

- Workshops: Expanding workshop,extraction workshop and refining

- Technology supports: 7 patents for oil equipment

- capacity: 10-500T

- Oil Residues: 1% max

- Worker Quantity: 3persons per shift

- Warranty: 1year

- Operation: Easy to operation

- type: oil refining machine

Soybean Oil Processing Byproducts and Their Utilization

Refining of soybean oil, to make a neutral, bland-flavored, and light-colored oil, results in several by-products. The by-products consist of various mixtures of phosphatides, unsaponifiables, glycerides, free fatty acids, and soap. Lecithin contains mostly hydratable phosphatides, together with some free fatty acids and neutral oil (glycerides).

For those reasons, refined soybean oil is widely used all over the world. Production of high quality meal and crude oil is the main objective in soybean processing. For achievement, thorough knowledge of the te chnical system and disciplined operation are required. The starting point is reception of soybeans at the processing plant.

Golden Oil – Golden Oil

Golden Oil is a pioneer in the refined vegetable oil industry in Nigeria. As an early leader in the edible oil refining business, we have built scale and excellence in every facet of our operations. In our plants we have built efficiency, in our products we infuse world-class nutrition and quality, and in our people we instill confidence in the

A soybean processing facility, in which refined oil, soy protein concentrate and soy protein isolate are produced, generates residues that if undergo additional industrial operations may result in

Soybean Oil Refining & Detailed Soybean Oil Refining Process

In the U.S.A. and in Europe, for soybean oil refining, the caustic soybean oil refining process is by far the most used. The physical refining of palm oil, lauric oils and other fats and oils that have a low phosphatide content by dry degumming and bleaching followed by distillation, deodorization, is 20 to 25 years old and common practice today.

Dangote refinery is a 650,000 barrels per day (bpd) integrated refinery and petrochemical project under construction in the Lekki Free Zone near Lagos, Nigeria. It is expected to be Africa’s biggest oil refinery and the world’s biggest single-train facility, upon completion in 2022. The refinery will process a variety of light and medium

Soybean Oil Extraction and Processing | SpringerLink

Abstract. Soybeans are the dominant oilseed in both U.S. and world markets. During a typical year soybean production comprises over half the worldwide oilseed production ( Anonymous 1995 ). However, according to Dutton (1981) in the early 1940s, soybean oil was considered a poor quality oil, not suitable for food use, and more appropriate for

Soybean oil quality varies by origin. These variations are due to the geographic location where the whole soybeans were grown, storage conditions and handling prior to processing. Variations in the quality of CDSBO can lead to a longer, more costly refining process, while simultaneously lowering refining yields. Understanding these variations

- How is crude soybean oil refining performed?

- Industrial refining of crude soybean oil was performed under the following conditions: degumming and neutralization was done by oil acidification with phosphoric acid (1.1 ml per oil L) and neutralization with NaOH (5 N) and centrifugation for the removal of phospholipids and free fatty acids.

- Does industrial refining of soybean oil reduce tocopherol content?

- In fact, industrial refining of soybean oil reduced the tocopherol content of the soybean oil from 132.92 to 119.09, while the content of tocopherols in the refined oil using the electrostatic field did not change significantly (Table 4 ).

- What is industrial refining of crude soybean oil?

- Industrial refining of crude soybean oil is thus essential (Pal et al., 2014) involving several steps, which may be physical (bleaching and deodorization) or chemical (neutralization, bleaching and deodorization).

- Why is electrostatic field used in soybean oil refining?

- To that end, an electrostatic field as a non-thermal technology was used for refining soybean oil so as to resolve the drawbacks of the industrial soybean oil refining as a complex and time-consuming process resulting in the loss of bioactive compounds in the oil due to high heat exposure.