use oil expeller sunflower oil make plant in ghana

- Usage: pretreatment,extraction,refining, crude oil refinery making mill building

- Production Capacity: according the capacity

- Model Number: 1-200T/D

- Voltage: 380V or 440 V

- Power(W): according the capacity

- Dimension(L*W*H): according the capacity

- Weight: according the capacity

- Certification: BV and CE

- solvent:

- residual oil in cake: 1%

- extractor type: rotocel extractor

- capacity: crude oil refinery making mill building

- Equipment material: Stainless steel or carbon steel

- Raw material: Sunflower Seed

- Extractor system: Toasting system

- Use:

- Solvent:

Ghana to start cultivating sunflower in large quantities in 2024

Presently, Ghana imports a minimum of USD 4 million worth of sunflower oil yearly for fish processing companies, which in turn export fish flakes in sunflower oil to the tune of USD 147 million

Sunflower Oil Uses. Beyond its production process and various uses of the plant, sunflower oil plays a unique role in different sectors. Fuel. Sunflower seed oil, a functional vegetable oil fuel can be blended with conventional diesel or processed into biodiesel and contributing to global transportation. Supplements

Sunflower Oil Production Plant Process Flowchart

The Sunflower Oil Processing Plant offered by GOYUM is robust, versatile, reliable and efficient. This Sunflower Oil Processing Plant is based on practically proven technology which is not only energy efficient & environment friendly, but also economical. Please fill the below Enquire Now Form so that we can contact and provide you the best

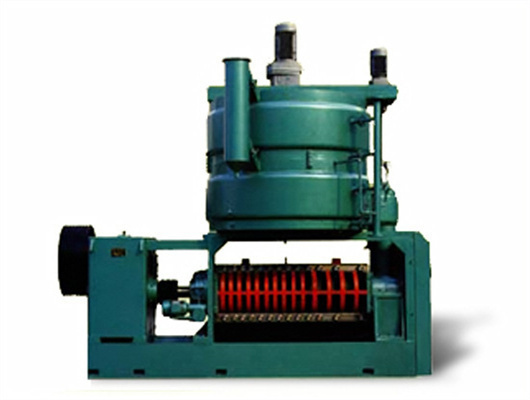

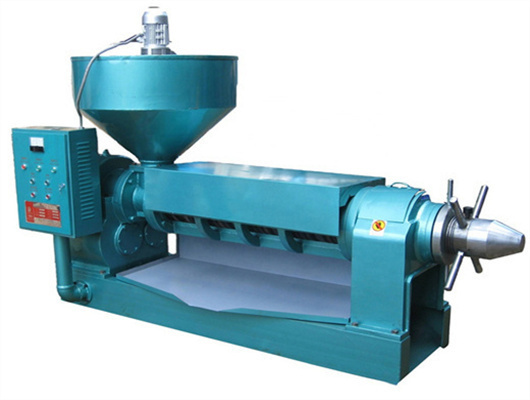

The expeller pressing method generally captures around 65% of the sunflower oil. Admittedly, create a lot of waste. Solvent extraction method can captures around 99% of the sunflower oil. Sunflower oil solvent extraction plant. If you want to know the details sunflower oil production process methods, you can read the following article

Expeller Pressed Sunflower Oil vs Solvent Extraction Methods

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier.

Presently, Ghana imports a minimum of USD 4 million worth of sunflower oil yearly for fish processing companies, which in turn export fish flakes in sunflower oil to the tune of USD 147 million annually. This is because fish processing companies are mandated by the US Food and Drugs Authority to use sunflower oil to prepare fish flakes.

Sunflower Oil Production Process Introduction - Edible Oil Expeller

The processing characteristics of first-grade sunflower oil are: First of all, sunflower seeds are selected and cleaned to remove impurities, and then the seeds are de-husked and crushed. After that the embryo is flaked and steamed in the frying pan, the fried product is pre-squeezed out of the oil and the remaining oil is extracted by solvent

The steps involved in Sunflower Oil Refining Process: Degumming. Neutralization. Water Washing. Vacuum Drying. Bleaching. De-waxing. Deodorisation. The chemical refining stages of Sunflower oil are also similar to other soft oils except dewaxing which is additional as sunflower oil contains wax which will be removed by dewaxing process.

- How to extract oil from sunflower seeds?

- The oil extracted from sunflower seeds either by Screw Press or by Solvent Extraction Process. The Seeds will be either dehulled or whole seed extraction is taking place based on the requirement of the protein content of the De-oiled Meal.

- Is sunflower oil Dehulled or whole seed extraction?

- The Seeds will be either dehulled or whole seed extraction is taking place based on the requirement of the protein content of the De-oiled Meal. Like other oils, sunflower oil also contains undesirable components like gums, tocopherols, sterols, wax and free fatty acids.

- How does a sunflower oil refinery work?

- The deodorized oil at high temperature will be used to exchange the heat energy with incoming oil to the system and further cooled to 45°C and allowed to pass through the polish filters and send to the Final refined oil storage tank. Are You Looking to Start a New Sunflower Oil Refinery Plant or Further Expansion?

- What is sunflower seed oil?

- Sunflower seed oil is the most ancient seed of North America which was cultivated during 3000 BC as per available records and it moved to Russia and from there to other countries. The most suitable temperature for the growth of sunflower seed is 20 ¨C 27°C with abundant water.