50t rice bran oil production equipment sunflower in congo

- Usage: Sunflower Oil, Sunflower EDIBLE OIL

- Production Capacity: 5TPD-100TPD

- Voltage: Based on the capacity

- Dimension(L*W*H): Based on the capacity

- Weight: 500 KG

- Warranty: 1 Year, 1 year backed Sunflower oil production line

- Core Components: Gearbox

- Oil type: Sunflower Oil

- Color: As you request

- Certification: ISO9001: 2015 CE

- Capacity: 1~10 tons per day oil production line

- Working Principle: Mechnical force to squeeze oil

- Function: Pressing crude vegetable oils

- Raw Material: Sunflower seed, Sunflower seed, Sunflower and more

- Advantage: High oil output Sunflower oil production line

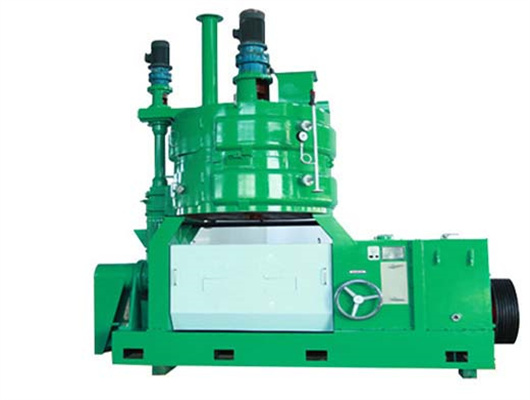

- Main Equipment: Screw oil press machine

Sunflower Oil Pressing Machine

Short Description: We offer professional small scale sunfloer oil pressing line from 1tpd to 20tpd with low price. Sunflower oil is a kind of common edible vegetable oil in our daily life. Sunflower oil is extracted from sunflower seed, due to rich nutrition. Quality characteristics of sunflower oil: light yellow color, clear; taste fragrant

At the same time, if you require, we can also provide technical support such as factory layout planning. The cost of sunflower oil processing machine varies from $32000 to $69500 depending on the equipment configuration. For customers with low initial investment budgets, production equipment mainly includes transportation equipment, roaster

Edible Oil Extraction Plant Products - vegetable oil extraction machine

1. 10-1000 t/d automatic complete production line of edible oil seeds (like groundnut , soybean, sunflower seeds , corn germ , cotton seeds, rice bran , palm) pretreatment and pressing. 2. 20-1000 t/d automatic complete rotary-type and ring-form extraction equipment. 3. 1-10 t/d small scale edible oil refining equipment.

The oil is extracted directly from the sunflower seeds by a screw type oil press machine. Sunflower seeds are cold-pressed (or hot pressed) at a certain temperatures, and the protein-rich cake that remains after the seeds are processed into oil is used as animal feed, retaining 99% of the nutrients in sunflower oil without the use of chemical solvents.

Life cycle assessment of rice bran oil production: a case study

Environmental problems caused by the food processing industry have always been one of the concerns for the public. Herein, for the first time, a gate-to-gate life cycle assessment (LCA) was employed to evaluate the environmental impact of rice bran oil production. Four subsystems, namely, transportation of the raw rice bran to oil factory, crude oil extraction, oil refining, and oil storage

De-shelled pressing-leaching technology is the key point of sunflower oil production line which avoids the negative impact of over-refining, high temperature, and acid and alkali effects on oils, so that the nutrients in the oil can be well preserved. For example, the content of vitamin E in de-shelled squeezed sunflower oil is 75.5mg/100g.

#1 Sunflower Oil Production Line For Sunflower Oil Plant

In this article, we will discuss the complete sunflower oil production process in detail. Step 1: Cleaning and Shelling. The sunflower seeds are first cleaned and shelled in an oil mill. This process involves removing any impurities and outer shells from the seeds. Step 2: Cracking.

With rich experience and advanced rice bran oil mill machinery technology in this field, KMEC is your reliable rice bran oil machinery manufacturer and supplier. The output rate of rice bran oil mill machinery is between 8-11% and the capacity is from 5t to 100t per day. In order to obtain high quality refined rice bran oil, the refining

- What are the steps and equipment for processing sunflower oil?

- More specifically, the operation steps and equipment for processing sunflower oil are as follows: 1. Sunflower Seeds Selecting 2. Shelling & Crushing 6. Crude Oil Refining

- What are the processing characteristics of first-grade sunflower oil?

- The processing characteristics of first-grade sunflower oil are: First of all, sunflower seeds are selected and cleaned to remove impurities, and then the seeds are de-husked and crushed.

- Does Ange kanonga eat sunflower oil?

- The vegetable oil produced by Kanonga¡¯s company, Mimosa Simence, is not only replacing oil imported through Zambia but it is also offering a healthier option ¨C her food products are organic. Ange Kanonga during an interview with some bottled sunflower oil displayed on the table. Photo: Rose Ngoy

- How many tons of sunflower oil can be refining per day?

- For the refining part, we provide a full set of equipment for batch refining process, semi-continuous refining process, and full continuous refining process (more than 50 tons per day). Batch refining process has a daily capacity of 1~30 tons of sunflower oil. It has features of less investment, convenient operation and small footprint.