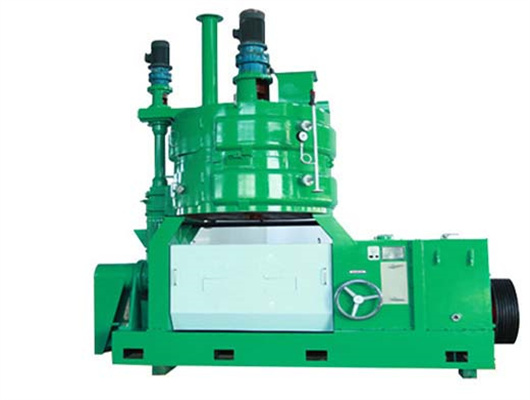

small sunfloweroil refined production equipment in mozambique

Mozambique Refined Sunflower Oil market overview 2024

Discover import data of Refined Sunflower Oil to Mozambique. Get import value, volume, price data, trends and more. The information below is based on the HS code 151211 (Vegetable oils; sunflower seed or safflower oil and their fractions, crude, not chemically modified). Get Premium Access.

Crude pressed sunflower oil obtained from a local oil mill was refined using chemical method by degumming, neutralization, bleaching and dewaxing. The quality and composition of crude and refined oil were compared. The phosphorous content, FFA content, peroxide value and wax content decreased during the refining process.

Trends of Refined Sunflower Oil production in Mozambique

Refined Sunflower Oil HS Code: 151211 - Vegetable oils; sunflower seed or safflower oil and their fractions, crude, not chemically modified FAO Code: 0268 - Oil, sunflower

A new cooking oil refinery, produced from soybeans and sunflower seeds, is being built in the city of Nacala-Porto, Nampula province, and should start operating next October. With the enterprise it is intended to reduce foreign dependence, since the country imports 80% of cooking oil consumed in the national market.

Sunflower Oil Refinery Plant Process

Sunflower oil contains phosphatides like other oils 0.5% to 1.5% based species and variety of the seed. This will be removed through the standard degumming process by addition 2% water and 1kg to 1.5Kg of food-grade phosphoric acid to the oil at 60°C and allowing to mix for 20 minutes and then by separating through the centrifugal separators.

In this article, we will discuss the complete sunflower oil production process in detail. Step 1: Cleaning and Shelling. The sunflower seeds are first cleaned and shelled in an oil mill. This process involves removing any impurities and outer shells from the seeds. Step 2: Cracking.

Sunflower Oil - an overview | ScienceDirect Topics

Sunflower oil is a health-benefitting oil due to its low content of saturated fats, high levels of PUFAs and monounsaturated fatty acids, and vitamin E. It has good oxidative stability, and the high-oleic sunflower oil is suitable for industrial frying. Lecithin, wax, and tocopherol are also obtained from sunflower oil.

Quality of sunflower oil The physico-chemical parameters of crude sunflower oil, refined oil obtained from the experimental unit and commer-cial refined oil sample is given in Table 1.Theoilsamples were found to be completely moisture free after refining and less than the maximum limit of 0.1 %. The specific gravity

- What is the equipment cost of sunflower cooking oil production line?

- Here we can give your some references on equipment cost of sunflower cooking oil production line: The cost of 5ton/day oil pressing line is about $5500. The cost of 1ton/day oil refinery plant is about $19800. For 1ton/day sunflower oil dewaxing machine, the price is about $13000.

- Why is refined sunflower oil popular in India?

- Refined sunflower oil has found wide acceptance because of its high polyunsaturated fatty acid content, bland flavour, good storage stability and low viscosity (Semwal et al. 1996). Refined sunflower oil has emerged as one of the most popular cooking oil in India.

- What is the main equipment of sunflower oil manufacturing unit?

- Main Equipment: Cleaning/screening machine, seeds cooker, oil expeller, oil filter press and conveyors. This sunflower oil manufacturing unit is effective, automated and affordable which makes it ideal choice for small scale sunflower oil factory. It is capable of continuous cooking oil processing plant.

- What is sunflower oil used for?

- Sunflower oil is a high-quality edible oil known as ¡°nutritive oil¡±, which has become the preferred oil for consumers and chefs. And the worldwide consumption of sunflower oil ranks third in all vegetable oils. It is generally used for cooking, for example, it is used to make margarine, mayonnaise, salad dressing and salad oil.