equipment required for peanut oil processing in zimbabwe

- Usage: edible oil extraction

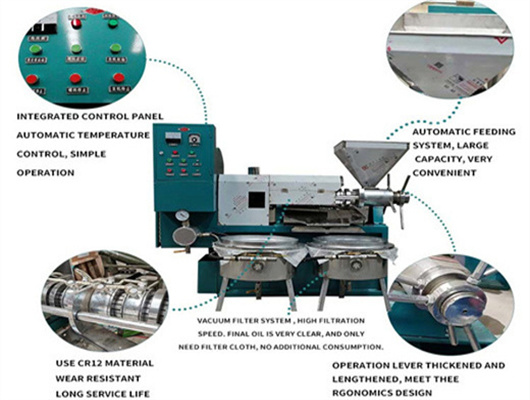

- Type: Peanut Oil Extraction Machine

- Production Capacity: 40-500 kg/h

- Voltage: 380V/50HZ

- Dimension(L*W*H): 880x440x770mm

- Weight: 160kg

- Core Components: Motor

- Product name: 6YL-68 Oil Press Machine

- Oil rate and lever: oil yield≥98%, cake≤5% , meal residual≤1% , lever 1,1st grade oil

- Material: carbon steel or stainless steel

- Key words: Peanut Oil Extraction Machine

- Raw material: Peanut,

- Quality: china best brand and quality

- After-sales service: provide longlife technical support

- Application: Agriculture Vegetable Seeds

- Color: According to your request

- After Warranty Service: Video technical support, Online support

- Certification: CE, ISO, BV

The status of the agro-processing industry in Zimbabwe with particular

Agro-processing activities can contribute to sustainable livelihoods through improved incomes, employment, food availability, nutrition and social and cultural well-being from a limited area of land (Simalenga, 1996; Proctor et al., 2000; Azama-Ali, undated). Small-scale food processing activities represent a potential source of livelihood for

A number of factors contribute to peanut oil quality including harvesting conditions, storage at the oil mill, and processing within the refinery. Peanuts are normally harvested in the fall when excessive rainfall is more likely and the moisture content may be above the 8–10% levels required for peanuts.

Peanut processing [en] - CTCN

The peanuts are first shelled and cleaned. They are then roasted at 425°F (218°C) for 40-60 minutes either a) on trays in an oven, the nuts being turned by hand from time to time or b) in equipment similar to that used for roasting coffee. This small rotary roaster allows each nut to become uniformly roasted.

The price of shelled kernel is approximately double that of pod. Hand shelling of peanuts is a time consuming and laborious process which is mostly used in the remote areas in Zimbabwe. Manual shelling of peanuts using “Manual Sheller’s” has been adopted to reduce the time invested in hand shelling.

A Complete Guide to Peanut Oil Production

What’s Inside the eBook. In this guide to peanut oil, we’ll examine the history of peanut production, explain how peanuts are processed into oil, and discover peanut oil’s diverse product applications as we explore this market’s global growth potential. The upstream processes of harvesting, cleaning, drying, and storing peanuts are

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Design of an Automated Powered Peanut Shelling Machine. - EUDL

consequently crushing the peanuts in the process. The Tensometer has readings in Newtons. 4. As the force is applied, a quick rise in the mercury level is observed. Mercury rise is proportional to the force crushing the peanuts. 5. The level to which the mercury rises shows the force required to crush the peanuts. 6.

In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization.

- How to extract oil from peanuts?

- Oil production requires some type of press with which to extract the oil form the groundnuts and filtering equipment. Practical Action has developed a simple manual screw press that would be suitable for extracting oil from peanuts, as well as many other agricultural crops.

- Can a screw press extract oil from peanuts?

- Practical Action has developed a simple manual screw press that would be suitable for extracting oil from peanuts, as well as many other agricultural crops. There are quite a number of presses of very similar design, they are simple to make, except for the screw which would have to be machined.

- What are the manufacturing processes of peanuts?

- Depending on what you want to make, some peanut manufacturing processes include roasting, frying, boiling, grinding, pressing, and coating the peanuts. Which peanuts equipment do you need? Manufacturers requiring big bag packaging have specific sizes, shapes, and material requirement…

- How to make peanut oil from groundnuts?

- According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking Step 4: Pressing Step 5: Filtration After harvesting groundnut are received at processing facilities.