oil pressing plant peanut oil extraction plant in rwanda

- Usage: Peanut Oil

- Type: oil refinery LD, rbd coconot processing line

- Production Capacity: 10TPD-500TPD

- Voltage: According to customer demand

- Power(W): According to project

- Dimension(L*W*H): According to project

- Weight: According to customer demand

- Certification: ISO9001-2008

- Color: Silver

- Production condition: One to three staffs

- Material: Carbon steel, stainless steel

- Raw material: Peanut Seed

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical principle

- Warranty period: One year

- English manual: Yes

- Factory visiting: Yes

Production, Processing, and Food Uses of Peanut Oilseed, Oil,

Peanut oil is considered as a premium edible oil and commands a high price in both US and European markets. In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United

2 Chemical Composition and Bioactive Compounds of Extracts from Peanut Oil-Processing By-Products. The edible kernel comprised about 68–72% of the peanut, while the balance 28–32% is the peanut hull [ 8 ]. Peanut kernel’s average thickness, width, and length are 6.9 mm, 3.6 mm, and 8.5 mm, respectively [ 9 ].

Groundnuts / Peanuts Solvent Extraction Plant Manufacturer - GOYUM

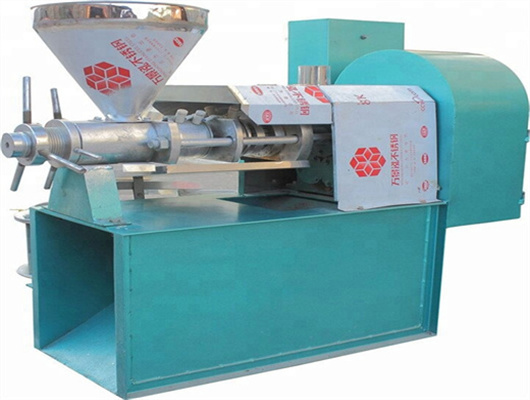

Groundnut Kernel Oil Extraction System. There are two types of methods for extraction of oil. First mechanical pressing using screw presses and second solvent extraction method. Under mechanical pressing the kernels will be carried out by two methods. Pre-press method followed by Solvent Extraction.

Groundnut Oil Filter Press. The filter press filters the extracted groundnut oil by using the micro filter cloths to make it edible. Filtered groundnut oil will be a very cleaned, transparent, fresh, pure and natural in taste without any chemicals and hence there is a big demand of the same groundnut oil at everywhere.

Peanut Oil Processing Technology

The conditioned peanut kernels are transported by a conveyor to the twin-screw press for cold pressing; the cold-pressed crude oil and cold-pressed peanut meal with low denaturation will be obtained. After the cold-pressed crude oil is filtered with frame filter, product oil is obtained, which will be packaged by a filling machine to form cold-pressed peanut oil products ( Fig. 3.8 ).

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Turnkey Peanut Oil Pressing Plants-CHEMSTA Group

Peanut Pressing Production Line (Pressing and solvent Extraction) The purpose of pressing is to get a portion of oil by mechanical pressing while providing pressing cakes for extraction plant. The processes: Seed Cleaning, Stone Removing, Weighing, Crushing, Flaking, Cooking, Pressing, Oil Residue Separation, Cake Extraction.

frying of peanuts before they are cold-pressed, with the resulting peanut oil then being filtered [ 20 ]. In 2017, Chen et al. examined the effects of pressing temperature and moisture content,