peanut oil solvent extraction processing equipment in malawi

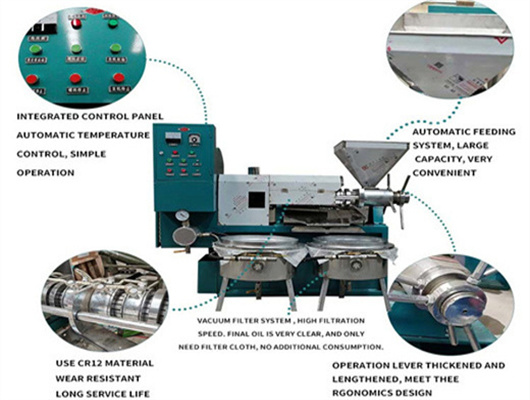

- Model Number:YZYX130WZ

- Type: Spiral Sunfower Oil Press

- Application: Peanut Cooking Oil Machine

- Appearance: Horizontal

- Press Materials: Peanut

- Processing Capacity: 8tons/24h

- Size: 2005*1610*2010mm

- Driving Force: Electricity or Diesel Engine

- Press Method: Hot or Cold Press

- Oil Press Power: 18.5kw

- Power for Filtration: 2.2kw

- Temperature Cotrol Power: 3.0kw

- Oil Content of Dry Cake: < 7.8%

- Weight: 1080kg

- Spiral Axes Rotate Speed: 32-44r/Min

- Advantage: Press Ability Is Stronger, Oil Yield Is Higher

- Transport Package: Wooden Box

- Specification: SGS, ISO, BV, CQC

- HS Code: 84792000

- Production Capacity: 400pieces/Month

Groundnut Oil Manufacturing Process With Flowchart - Goyum

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

In the past few decades, aqueous extraction processing (AEP), has been developed to separate oils and proteins from oil-containing starting materials (Fig. 1 [30] and Fig. 2 [31]). This method uses water as an extraction solvent, rather than an organic solvent [15, 32]. In AEP, oil is extracted because it is insoluble in water and floats in hot

Defatting and Defatted Peanuts: A Critical Review on Methods of Oil

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

The solvent extraction method recovers almost all the oils and leaves behind only 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant etc. In the case of mechanical pressing the residual oil left in the oil cake may be anywhere from 6% to 14%.

Groundnut Oil Mill Plant

Groundnut Oil Mill Plant. GOYUM SCREW PRESS is a leading manufacturer of groundnut / peanut / earthnut oil mill plants. We have exported oil mill machinery and equipment for customers around the world. Our groundnut oil extraction machines are successfully running in India, Nigeria, Tanzania, Chad, Senegal, Cameroon, Ethiopia, Niger, Ghana

The leaching procedure mainly makes use of the solid-liquid extraction principle to select certain fat-dissolving organic solvents to extract the peanut oil. Generally speaking, the leaching solvent should meet the following conditions: good fat solubility, stable physiochemical properties, easy separation from the fat and meal, and be safe, cost-effective, and easy to get.

Peanut oil | Journal of the American Oil Chemists' Society - Springer

Conventional expeller and expeller/solvent extraction processes for peanuts are compared to the nonconventional processes of direct solvent extraction, cold pressing and nonhexane solvent processes. Peanut composition, cleaning and specific extraction procedures have a major impact on finished crude oil composition, refining characteristics, final oil and meal quality and utility. Special care

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What is peanut pretreatment technology?

- Pretreatment Technology Peanut pretreatment refers to a series of treatment processes before oil production, such as cleaning, shelling, grading and selection, drying, cooling, thermal conditioning, pressing, and cooking.

- What is peanut oil processing technology?

- This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology.

- How is peanut oil extracted?

- Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking