natural peanut oil extraction plant in togo

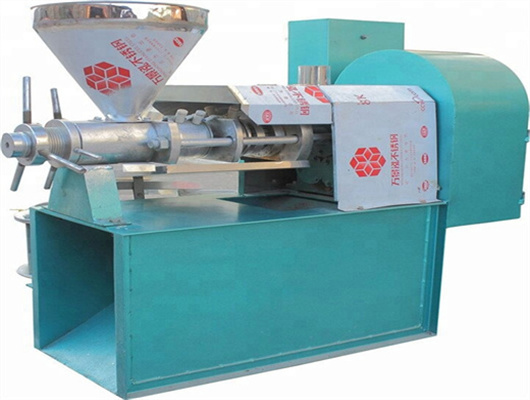

- Usage: Peanut oil refinery, Peanut oil refinery

- Type: Peanut oil refinery

- Production Capacity: 80kg/h, 500kg/h, 100kg/h

- Voltage: 220V/380V

- Power(W): according to the different capacity

- Dimension(L*W*H): 1200*400*900mm3

- Weight: according to the different capacity

- Certification: CE ISO, CE and ISO

- Material: carbon steel or stainless steel

- Capacity: 5-600T/D Peanut oil refinery

- Pakaging: according to customer's requirement

- Raw material: Peanut Seed

- Operation: easy operation and saving energy

- Warranty period: 1 year

- Delivery time: 1-2 months according to your capacity

- Feature: high quality refined oil

Peanut Soybean Oil Production Line Set up in Togo | Project

The main oil crops in Togo is peanut, cotton seed, oil palm, soybean and more. But, the edible oil production industry in Togo is relatively small and its consumption of cooking oil is increasing in these years. So, it is a great opportunity to setup a cooking oil production plant in Togo to get more profits.

Due to its high oil content, it is categorized as both a grain legume and an oil crop. A vegetable oil made from peanuts is called peanut oil, commonly referred to as groundnut oil or arachis oil. When prepared using roasted peanuts, the oil has a greater peanut flavor and scent compared to the ordinarily mild or neutral flavor . Vitamin E, an

Production, Processing, and Food Uses of Peanut Oilseed, Oil

In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization.

Estimated Cost per Ton ($) Peanut Oil. $800. Palm Oil. $900. Sunflower Seed Oil. $700. Please note that these amounts are for illustrative purposes only and may not reflect the actual current market prices. It's essential to consult the latest data and conduct a thorough cost analysis for accurate estimations.

Comparison of cold-pressing and soxhlet extraction systems

Antioxidant activities of different nut oils ranged from 11.43 (peanut) to 65.58% (pistachio) in cold pressed oils whereas in case of soxhlet extracted oils they were in the range of 11.32 (hazelnut) to 51.28% (pistachio). β-Carotene contents of oils obtained by cold pressing and soxhlet extraction changed between 7.53 (almond) and 13.58 µg

10TPD Peanuts & Ground Oil Production Plant Business Started in Togo. Groundnut oil has many uses: it can be used as edible oil. It contains high content of unsaturated fatty acids and low content of saturated fatty acids, which is good for lowering cholesterol and preventing heart disease; it can also be used to make ointments; it is the

Aqueous enzymatic extraction of peanut oil body and protein

Aqueous enzymatic extraction (AEE) is a new technology for extracting vegetable oil body which has the advantages of low energy consumption, product safety, mild reaction conditions, and simultaneous separation of oil and protein. Among the enzymes tested in the present work, Viscozyme L (compound plant hydrolase) exhibited the highest extraction activity during peanut oil extraction

Oilseeds are crucial for the nutritional security of the global population. The conventional technology used for oil extraction from oilseeds is by solvent extraction. In solvent extraction, n-hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to solvents. However, usage of hexane as a

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- How to make peanut oil in China?

- Currently, there are two pressing methods: high-temperature pressing and cold pressing. More than 90% of oil production in China adopts the traditional technique of high-temperature pressing, and the peanut oil produced with this method has a strong fragrant flavor and is therefore greatly favored by consumers.

- How is peanut oil extracted?

- Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization. The food uses of peanut oil and protein are reviewed in this article.

- Is oil extraction from peanuts environmentally friendly and cost-efficient?

- A comparison in terms of productivity, efficacy, specificity, quality of the extracts, and operating conditions was conducted, which favored the novel methods as being mostly environmentally friendly and cost-efficient. Chemical methods of oil extraction from peanuts.