pressing peanut mini oil press plant in togo

- Usage: FLAXSEED

- Production Capacity: 1-100TPD

- Voltage: 240-460V

- Power(W): 22kw

- Dimension(L*W*H): 40m*30m*16m

- Weight: 30tons

- Certification: CE

- After-sales Service Provided: Overseas third-party support available

- Machine type: processing plant for flaxseed oil

- Refining method: Physical or Chemical

- Oil standard: 1st to 4th class oil

- Processing capacity: 1-100tpd

- Heating method: steam heating

- Cooling method: circulated water

- Steam consumption: less than 300kg/ton

- Water consumption: 300kg per ton oil

- Electricity consumption: 22kw per ton oil

- Bleaching earth: 3-1000kg per ton oil

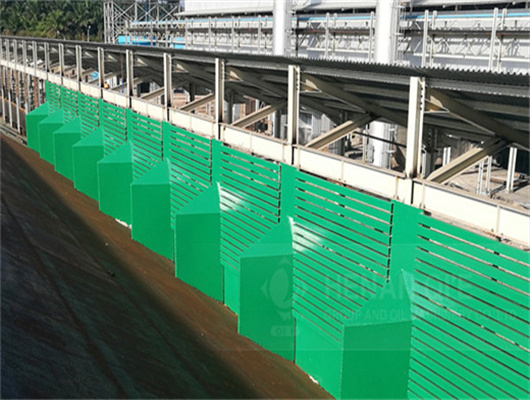

10TPD Peanut Oil Mill Business Plant Built In Togo

Project Site: Togo. Capacity: 10TPD Peanuts & Ground Oil pressing and 3 TPD Peanut Oil Refinery Manufacturing. Final Product: crude and refining ground / peanut oil. Production Technology: Peanuts Pressing and pressing Line . Main Equipment: Groundnut Shelling Machine, Cleaning Sieve, Cooking or Roasting Machine, Screw Oil Press, Oil Filter

In order to help more people to setup their own oil pressing line at low cost, Hongde Machinery specially designed the small scale oil production line with capacity of 1tpd to 30tpd for optimal choice. Capacity. 1TPD, 3TPD, 5TP, 10TPD, 15TPD, 20TPD, 30TPD and Above. Investment Cost. $7,000 ~ $50,000 ( The EXACT cost is decided by the capacity

Insights into Mini Oil Production | Equipment Selection

Oil Pressing Process: The cleaned seeds undergo a pre-pressing stage using a screw oil press machine. This step extracts a portion of the oil from the seeds and leaves behind oil-rich cake. Oil Extracting Process: The pre-pressed cake is then subjected to solvent extraction with the help of a solvent extractor.

The single pressing method is used in peanut oil pressing to extract oil from the kernels. The actual compression ratio of pressed material is 4-4.5, which is larger than soybean obviously, so the compression ratio should be 10 or so when using the screw oil press. The oil discharge gap of the press cage should be broadened and lengthened

Multi-functional Automatic Small Oil Press Machine

This type of multi-functional automatic oil extracting machine can be used to extract oils from a very wide range of plant seeds and nuts, including soybean, mustard, peanut/groundnut, sesame, palm kernel, cottonseed, sunflower seeds, coconut/copra, tea seeds, flaxseeds, and more. And, it is now very popular in the edible oil making market

In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization.

Building Your Small Scale Oil Press Plant with Limited Cost

Small scale oil press plant, also called mini oil mill project, is manufactured with small production capacity ranging 0.8-20 t/24h. Although designed with small specification, it is composed of complete equipment, including cleaning sieve, cooker, oil expeller, oil filter. But, the process is not always the same, different raw oil seeds

The oil content of the peanut kernels and the choice of pressing method (cold or hot) can also influence the oil yield. For example, manufacturers offer different types of machines, such as a spiral peanut oil press and commercial automatic oil press machine, respectively, to cater to various production scales and needs.