design of sunflower oil extractor in ghana

- Usage: Sunflower OIL, Cooking Oil

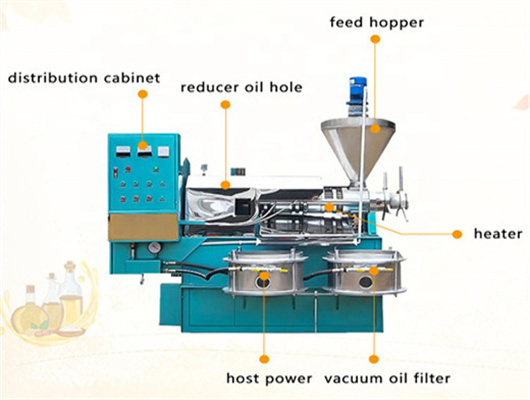

- Type: Sunflower Oil Press Machine

- Production Capacity: 13.5 kg/batch

- Voltage: 220v/380v/customizable

- Dimension(L*W*H): 750*1010*1640 mm

- Weight: 1230 kg, 1230 kg

- Core Components: Motor, Hydraulic system

- Product Name: Sunflower oil press machine germany Sunflower cooking oil squeezing

- Model: 6YY-270

- Pressure: 60Mpa

- Power: 2.2 kw

- Capacity: 13.5 kg/batch

- Dimension: 750*1010*1640 mm

- Advantage: Long Service Life

- Features: Easy to Operate

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: India, Colombia

- Certification: ISO CE

Design and Construction of Oil Expeller Press with

Plate 1: Side View of the Oil Palm Screw Press (Adetola et al., 2012) Results of performance test showed that the highest oil extraction ratio (OER) of 17.90% and oil extraction efficiency (OEE

exports sunflower oil to over than 100 countries of the world, which requires more efficient technologies for its production for the purpose of providing with world demand. For today, there are two methods of extracting oil plant raw materials: press and extraction. The advantage of the extraction method is the high degree of oil extraction of

884 A New Twin-Screw Press Design for Oil Extraction

Dehulled se are sflaked from dehulled sunflower se with d atwin,crew pr iss to 0.35 mm to rupture cell structures and free the oil, highly efficient. steam-cooked and partially dried, then expressed at 80-105°C and 4-7% moisture until 15-18% oil remains. KEYWORDS: Dehulled sunflower seeds, oil expression, The twin,screw 3-4 mm thick presscake

Bravi et al. [7] designed and optimized a continuous process for the sunflower oil extraction by supercritical CO 2. Salgin et al. [1] separated the skin from the germ before milling. The milled germs were then divided into four granulometric classes having mean diameter equal to 0.23, 0.55, 1.09 and 2.18 mm, respectively. The samples were then

Design, fabrication and performance evaluation of centrifugal

Lack of effective machines for dehulling sunflower seeds has resulted in high oil losses during extraction, especially for small- and medium-scale enterprise. This paper reports on the design, fabrication and performance evaluation (in terms of throughput capacity, dehulling efficiency and kernel breakage efficiency) of a centrifugal machine

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on

A new twin-screw press design for oil extraction of dehulled

A new twin-screw press design for oil extraction of dehulled sunflower seeds. Transport of material in a single-screw press depends mainly on friction between the material and the barrel’s inner surface and the screw surface during screw rotation. Thus, a solid core component, like seed hulls, is often necessary to produce the fraction.

Supercritical carbon dioxide (SC-CO 2) extraction of sunflower seed for the production of vegetable oil is investigated and compared to conventional methods.The effects of extracting variables, namely pressure, temperatures, particle size, SC-CO 2 flow rate and co-solvent, on SC-CO 2 extraction are investigated.

- Can supercritical carbon dioxide extract sunflower seed for vegetable oil?

- Supercritical carbon dioxide (SC-CO 2) extraction of sunflower seed for the production of vegetable oil is investigated and compared to conventional methods. The effects of extracting variables, namely pressure, temperatures, particle size, SC-CO 2 flow rate and co-solvent, on SC-CO 2 extraction are investigated.

- Does reduced quadratic model predict extraction yield of sunflower seed oil?

- Thus, the cumulative extraction yield predicted by reduced-quadratic model lie within ?3.62% to +3.59 of experimental values. Fig. 2. Parity plot for the reduced quadratic model, Eq. (5), developed for the prediction of extraction yield of sunflower seed oil extraction.

- Does Ukraine export sunflower oil?

- It should be emphasized that Ukraine exports sunflower oil to over than 100 countries of the world, which requires more efficient technologies for its production for the purpose of providing with world demand. For today, there are two methods of extracting oil plant raw materials: press and extraction.

- How does pressure affect the extraction yield of sunflower oil?

- This is due to the solubility of sunflower oil in supercritical carbon dioxide increases at higher pressures even though mass transfer coefficients decreases with a rise in pressure. Fig. 3.1a, Fig. 3.1b, Fig. 3.1c, Fig. 3.1d, Fig. 3.1e shows that cumulative extraction yield is highly sensitive to pressure as compared to other parameters.