morocco 20 100tpd peanut oil extraction plant in ethiopia

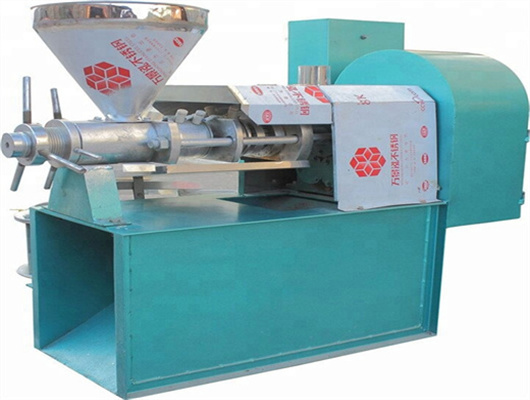

- Usage: beans/Peanut etc

- Type: Peanut Oil Extraction Machine

- Production Capacity: 3-500 kg/h

- Model Number: DL-ZYJ04

- Voltage: 180V-240V/50-60HZ

- Power: 350w/400w

- Dimension(L*W*H): 47.5*25*41cm

- Weight: 12kg/14kg

- Used for: Peanut/ Peanut/ nuts/ Peanut/ vegetable seeds/flaxseeds

- Keep working: 24 hours

- Color: Stainless steel

- Feature: Cold/hot pressing

- Advantage: Easy use,energy saving

- Advantage: : Simple operation

- Packaging Detail: Bubble foam

- Carton size: : 47.5*25*41cm

- Name: Peanut oil making machine price in sri lanka for sale

- Certification: CE

50 TPD Extruded Soybean Oil Extraction Plant With GOYUM 1500 - YouTube

GOYUM Extruded Soybean Oil Extraction Plant started its production in Ethiopia.This 50 TPD Oil Extraction Plant is installed with Seed Preparation, Extrusion...

Aqueous enzymatic extraction (AEE) is a new technology for extracting vegetable oil body which has the advantages of low energy consumption, product safety, mild reaction conditions, and simultaneous separation of oil and protein. Among the enzymes tested in the present work, Viscozyme L (compound plant hydrolase) exhibited the highest extraction activity during peanut oil extraction

Groundnut Oil Mill Plant

Groundnut Oil Mill Plant. GOYUM SCREW PRESS is a leading manufacturer of groundnut / peanut / earthnut oil mill plants. We have exported oil mill machinery and equipment for customers around the world. Our groundnut oil extraction machines are successfully running in India, Nigeria, Tanzania, Chad, Senegal, Cameroon, Ethiopia, Niger, Ghana

ESIA for Proposed Etete Solvent Extraction Plant iii new plant whilst the general buildings will be demolished. Additional infrastructure to be constructed consists of sections to accommodate oil seed storage, seed pre-cleaning, an oil mill, solvent extraction, meal and oil tanks as well as facilities for administration, fuel supply and packaging.

Peanut proteins: Extraction, modifications, and applications: A

The yield of free oil extracted from roasted peanut (150 °C, 20 min) using the AEP method was around 92.2% using the optimized processing conditions: solids-to-liquid ratio = 1:5; pH = 9; temperature = 60 °C, and time = 2 h [33]. Liu et al. (2020) investigated a combination of AEP and membrane separation for peanut protein extraction.

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Review on Quality and Safety of Edible Oil in Ethiopia

safety of samples collected from different city in Ethiopia (local. and imported edible oil) which is in the rapidly growing Ethiopi-. an edible oil supply-chain. According to the research report

A set of Multi Seed oil Processing plant was installed in Ethiopia recently having an input capacity of 60 tons per day. This soya oil plant includes a series of oilseeds processing equipment, such as an Elevator, Screw Conveyor, Seed Cleaner, De-stoner, Seed Cracker, Soybean Extruder and Screw Press to extract Oil & High-Protein Soymeal.

- How to make peanut oil from groundnuts?

- According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking Step 4: Pressing Step 5: Filtration After harvesting groundnut are received at processing facilities.

- How is peanut oil extracted?

- Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking

- What is groundnut oil manufacturing process?

- Groundnut oil manufacturing process is divided into two methods, the first is mechanical pressing and the second is solvent extraction. Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method.