peanut oil equipment for pretreatment prepressing in bangladesh

- Usage: Peanut oil/ Peanut oil/ Peanut oil/ Peanut Oil

- Type: Peanut Oil Extraction Machine

- Production Capacity: Press cake residual: ≤ 5%

- Voltage: 380V (can be customized)

- Dimension(L*W*H): 185*50*130cm

- Weight: 600 KG

- Core Components: Other

- Oil type: Peanut Oil

- Machine related name: oil press

- Related machine: oil press machine

- Machine type: mini oil press machine

- Machine function: Oil pressing

- Other machine usage: Screw oil expeller machine

- Machine processing capacity: 50-500kg/hour (Higher capacity at request)

- Machine material: Stainless steel

- Related keyword: oil pressers

- Main feature: oil extraction machine

- Related machine product: oil presser machine

Peanut Oil Processing Technology

After sedimentation, the crude oil is pumped into the frame filter for filtration, and the filtered product oil will be filled and packaged by a filling machine to form superfine fragrant peanut oil products (Fig. 3.9). Download : Download full-size image; Figure 3.9. Flow chart of equipment for superfine fragrant peanut oil production.

to oil; SSA is specific surface area of emulsion; D 3,2(μm) represents surface-area averaged particle size of emulsion; ρ oil represents density of peanut oil and ρ oil=0.91 g/cm 3. 2.6 Microstructure observation of peanut and OBs 2.6.1 Transmission electron microscope(TEM) Peanut seeds were cut into 1~2 mm3 chunks, soaked in

Hongde Machinery Oil Machinery

Hongde Machinery Machinery specializes in the production of large-scale oilseed pretreatment and pressing, oil extraction, oil refining equipments. Oil Equipment Factory. Powerful ODM Service. Overseas installation. Professional Expert Team. Complete oil & fat solution. Get A Detailed Quote. Learn More.

Effects of dry and wet grind on peanut oil and protein yield, oil bodies (OBs) stability, fatty acid composition, protein composition and functional characteristics were systematically analyzed. Results showed that peanut oil and protein yields reached highest at dry grind 90 s (92.56% and 83.05%, respectively), while peanut oil and protein yields were 94.58% and 85.36%, respectively, at wet

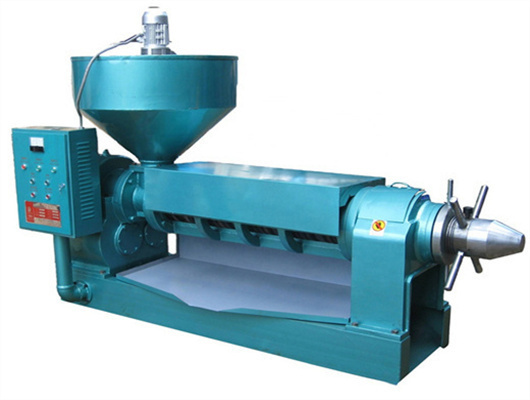

Oil Pretreatment And Prepressing And Extraction Machine For Peanut

Peanut Soybean and Sesame cooking oil production line . 1. Soybean pretreatment workshop . It ’ s used to process soybean into suitable condition for extraction through cleaning, stones removal, impurities removal, crushing, softening and conditioning, flaking ,drying and other processes.

Main equipments of peanut oil pretreatment & pre-pressing machine: Cleaning: Remove impurities such as leaves, sticks, stones, sand, dirt, spoiled seeds and metal contaminants. This process is commonly referred to cleaning machine, such as magnetic selector, de-stonner and cleaning sieve. Cleaning section can avoid destroy other peanut oil

manufacture of Pressing machine/ prepressing machine_Pretreatment/Press

manufacture of Pressing machine/ prepressing machine,Pressing machine/prepressing machine derived oil from oil seeds with mechanical power. Pressing machine/prepressing machine/oil press is always used in oil processing such as peanut, sunflower seed, sesame,etc.

Rapeseed, flaxseed pretreatment and prepressing plant including cleaning, stoner, weighting, softening, flaking, cooking, prepressing, residue separation section, ect.Raw materials through concentrated feeding mouth into the vibratory cleaning sieve, under reciprocating motion of the sieve body, raw material evenly distributed throughout the screen surface, and automatic grading, through the

- What is peanut oil processing technology?

- This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology.

- What equipment is used for cold pressing of peanut oil?

- Figure 3.8. Flow chart of equipment for cold pressing of peanut oil. 2. First, a sheller is used to shell the peanuts, and then the peanut kernels are transported to the low-temperature drying oven to be dried after being subjected to precleaning, gravity/magnetic separation de-stoner cleaning, and grading.

- What is peanut pretreatment technology?

- Pretreatment Technology Peanut pretreatment refers to a series of treatment processes before oil production, such as cleaning, shelling, grading and selection, drying, cooling, thermal conditioning, pressing, and cooking.

- What is oilseeds pretreatment equipment?

- Oilseeds Pretreatment Equipment for Cleaning, Shelling, Drying, Roasting,Crushing… Oilseeds cleaning equipment, like sieve cleaning machine, winnowing machine, magnetic separator, is able to clean nearly all kinds of vegetable seeds, nuts, grains, beans and other granular raw material from stone, dust, impurity or bad ones.