peanut solvent extraction plant oil refinery in durban

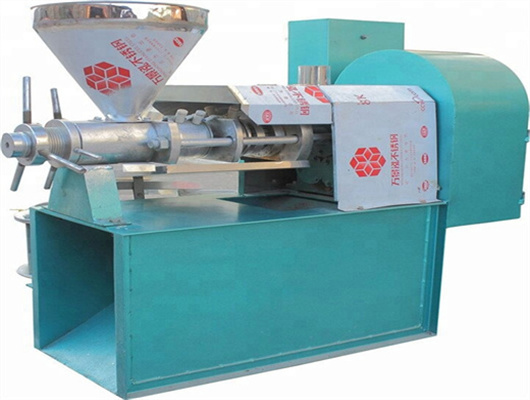

- Usage: crude edible oil refining machine

- Type: Edible Oil Refinery Machine

- Automatic Grade: Automatic

- Production Capacity: 100% crude oil price

- Voltage: 220V/380V/440V

- Certification: CE/BV/ISO9001

- Raw material: peanut/sunflower/sesame/soybean/crude oil

- Name: crude edible oil refining machine

- Application: crude oil price

- Common capacity: 1-1000TPD

- Warranty: 12 months

- Character: semi-continuous,fully continuous

Oil refinery closures, cleaner fuels and security of supply

Oil refinery closures, cleaner fuels and security of supply in South Africa. Firefighters putting out a fire at an Engen oil refinery on 4 December 2020 in Durban, South Africa. Gallo Images via

This oil extraction yield increases significantly to 6.29 and 89.20% at 30 and 180 min extraction times, respectively, when the ethanol solvent (7%) was added in the SCCO 2 extraction system as a co-solvent. Then, it could approach to 7.47 and 93.52% at 30 and 180 min extraction times, respectively, when the amount of ethanol co-solvent

Groundnut Oil Manufacturing Process With Flowchart - Goyum

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

The solvent extraction process produces high-quality lubricating oils characterized by good thermal and oxidation stability, light color, and a good additive response. The byproduct extract phase produced in the Solvent Extraction Unit is rich in aromatics and is used as a carbon black feedstock, rubber extender oils, and many other non-lube uses.

Balaji Engineering – We are leading manufacturer of Solvent

We are pleased to confirm our entire satisfaction of the working of expanded Solvent Extraction plant initially supplied by you of capacity 200 TPD. We are today getting a production of 300TPD and are fully satisfied with the capacity, consumption of utilities, hexane loss and steam consumption of our Plant

The solvent extraction process recovers almost all the oils and leaves behind 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant, etc. In the case of mechanical pressing, the residual oil left in the oil cake can be anywhere from 6% to 14%.

Solvent extraction | Oil Refinery Plant

Solvent extraction, whose basics are taught to people who learn chemistry in the classroom as they learn more about the analysis and separation of chemical samples, is commonly used by laboratories in the purification process of their samples. In addition, since it makes it possible for people to gather useful information that enables them to

Peanut oil extraction plant. 2015-10-16 14:31; Edible oil plant solutions; Get price; Our company is professional in peanut oil extraction plant design, installation, trial run, technical trainning and so on. We can provide you the turn key project of the whole peanut oil extraction plant from 20 to 2000TPD .

- How is peanut oil extracted?

- Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking

- What is groundnut oil manufacturing process?

- Groundnut oil manufacturing process is divided into two methods, the first is mechanical pressing and the second is solvent extraction. Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method.

- How does peanut oil refining plant work?

- After being treated, the solvent in the mixed oil is evaporated and enters the solvent condensation recovery system.The peanut oil will be fed into the peanut oil refining plant. The solvent evaporated by the mixed oil evaporation system passes through the condenser, and then is stored for recycling in the next production.

- What is solvent extraction of peanut oil?

- The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.