sunflower oil extractor solvent and mechnical in congo

- Usage: Sunflower oil

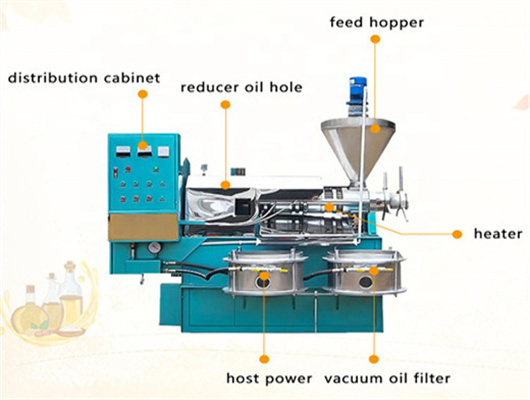

- Type: stainless steel alibaba Sunflower oil extraction mill

- Production Capacity: high

- Voltage: 220V, 380V, or other

- Power(W): 11KW

- Dimension(L*W*H): 2300*1650*1600mm

- Weight: 1200 KG

- Certification: CE, ISO9001, BV, etc..., BV, ISO9001, CE, etc..

- Color: depend on requirements

- Solvent consumption: ≤ 2Kg/T (No.6 solvent oil)

- Crude oil moisture and volatile matter: ≤ 0.30%

- Capacity: based on requirements

- Residual oil in meal: ≤ 1%

- Use: use Sunflower seed oil extraction mill to make oil

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Power consumption: ≤ 15KWh/T

Sunflower Seed Preparation and Oil Extraction

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on

The fatty acid methyl esters extraction of sunflower oil using a CLEXTRAL BC 45 co-rotating twin-screw extruder increased oil extraction yield up to 96% and decreased residual oil content in cake meal below 5% under solvent-to-solid ratio of 0.70 (Amalia Kartika et al., 2003). In addition, the solvent-to-solid ratio and the screw configuration

884 A New Twin-Screw Press Design for Oil Extraction

KEYWORDS: Dehulled sunflower seeds, oil expression, The twin,screw 3-4 mm thick presscake hasto be conditioned at press. 10-12% moisture andflaked to0.2-0.3 mmthickness for further solvent extraction. Final defatted meal of about 28-44% protein content, depending onthe xtent of Industrial extraction of edible oil from oilseeds orother dehulling

Summary. Solvent extraction is the preferred method for the final separation of oil from oleaginous materials containing less than 30% oil by weight. For oleaginous materials with less than 30% oil by weight, such as soybeans, cottonseed, dry process corn germ and rice bran, the material is mechanically and thermally prepared and then sent to

Review Optimization Methods for the Extraction of Vegetable

2.1. Mechanical Extraction (ME) Mechanical extraction is one of the oldest methods used for oil extraction. In principle, the seeds are placed between barriers where the volume available to the seed is reduced by pressing thereby forcing oil out of the seeds [20]. For application in rural areas, mechanical extraction is habitually used

The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL). The agitation rate was kept constant in all experiments, being sufficient to maintain a well-mixed fluid and the particles in suspension.

Green solvents and technologies for oil extraction from

The conventional technology used for oil extraction from oilseeds is by solvent extraction. In solvent extraction, n -hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to solvents. However, usage of hexane as a solvent has lead to several

Advantages of mechanical extraction include the production of good quality oil and the possibility of the use of its cake compared to when extraction is done in solvents. Oil extraction by mechanical presses is the most common and entails the use of either hydraulic presses or screw presses driven by a motor [2,21].

- How is sunflower crushed for oil recovery?

- Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

- Can ethanol extract oil from sunflower collets?

- Ethanol extracts less crystallizable waxes and more tocopherols and phospholipids. Ethanol showed great ability of extracting sugar, mainly raffinose and sucrose. The ethanolic extraction of oil from sunflower collets was studied and compared with previous data where hexane was used as extraction solvent.

- Which extraction method is best for sunflower seeds?

- Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

- What is a prepress solvent extraction method in a sunflower crushing plant?

- In a typical sunflower crushing plant using the prepress solvent extraction method, the initial steps of seed pre-cleaning and seed drying are located in the seed receiving section of the facility, prior to seed storage.