high yield hot edible soybean oil expeller in congo

- Core Components: Soybean oil filter press plate,membrane filter plate

- Voltage: up to Soybean oil plant

- Power: up to Soybean oil membrane filter press

- Weight: 9000 kg

- Dimension(L*W*H): up to Soybean oil filter press machine size

- Filter press application: Soybean oil extraction plant

- application for oil filter press: Soybean oil filter press

- oil filter press model: Soybean oil filter press

- Soybean oil filter press cloth: special filter press cloth for Soybean oil filtration

- Soybean oil filter press cloth: special for Soybean oil filtering

- Soybean oil pump: special for paml oil feeding pump

- Soybean oil filter press machine design: full automatic Soybean oil system

- filter press operation: automatic designed operation system

- filter press plates: mixed pack filter press plates for Soybean oil

- filter press manufacturer: Leo Filter Press

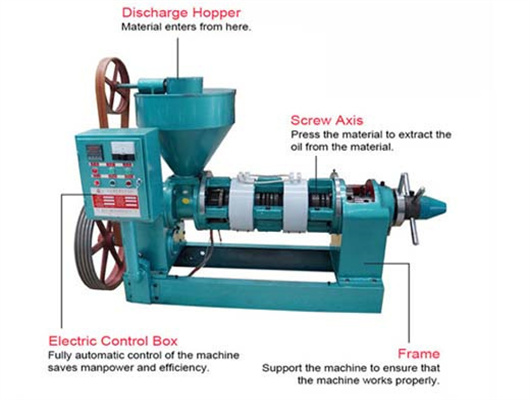

Mechanical Continuous Oil Expression from Oilseeds: A Review

The oil extraction by mechanical pressing is the most common method for continuous treatment of oleaginous seeds without solvent. Different types of presses can be used depending on the purpose (expeller, expander, and twin-screw extruder) and on the capacity range (3 kg h−1 to 150 t day−1). At the laboratory scale, many authors have highlighted the effect of operating parameters (screw

DESIGN AND FABRICATION OF A HIGH-YIELD EDIBLE OIL EXPELLER SCREW SHAFT. March 2023. INTERANTIONAL JOURNAL OF SCIENTIFIC RESEARCH IN ENGINEERING AND MANAGEMENT 07 (03) DOI: 10.55041/IJSREM18000

Full article: Effect of Pre-Treatments on Mechanical Oil

The optimum conditions for getting maximum oil expression and better quality of natural soybean oil by commercial oil expeller were the screw speed at 45 rpm, and the extrusion as a pretreatment. The optimized dependent variables at this condition were estimated as capacity 103 kg/h, oil recovery of 70.5%, and urease activity of 0.15.

Over recent years, the food industry has striven to reduce waste, mostly because of rising awareness of the detrimental environmental impacts of food waste. While the edible oils market (mostly represented by soybean oil) is forecasted to reach 632 million tons by 2022, there is increasing interest to produce non-soybean, plant-based oils including, but not limited to, coconut, flaxseed and

Hot Pressing VS Cold Pressing - Oil Expeller. Edible Oil

There are two types of oil press, cold pressing, and hot pressing. Just as the name implies, the cold pressing means pressing under low temperature, the oilseeds can be pressed without roasting. While hot pressing is pressing under high temperature, the oilseeds are pressed after roasting. There is special oilseed roasting machine for use.

Two-stage pressing technologies are used to maximize yield especially in oilseeds high in oil content (above 30 % - e.g. rapeseed, sunflower seed). Soybean pressing (oil content ca. 20 %) usually employs one-stage pressing. Cold or hot pressing - indicates the temperature at which the pressing is done.

Oil Recovery from Soybeans

Recovery of Oil from Soybeans. Today's new soybean processing plants using direct solvent extraction need to be capable of processing at least 2,700 metric tons per day (3,000 tons/day) to be economically viable in the United States, representing an investment of over $75 million.

Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%. Soybean oil and soybean meal contributed about 25% and 75% of total revenues, respectively.

- What is soybean processing?

- Soybean processing can be broken down into two (if screw pressing) or three (if solvent extracting) major areas: preparation (cleaning, dehulling, flaking, expanding), extraction (screw pressing, solvent extraction), and oil/meal finishing (oil and meal desolventizing, oil cooling and filtering, and meal toasting, drying, cooling and grinding).

- How profitable is soybean oil & soybean meal?

- Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%. Soybean oil and soybean meal contributed about 25% and 75% of total revenues, respectively. Through fluctuations in economic conditions, soybean meal plays an important role in earning profits, making the whole mechanical process profitable.

- Can two-stage extruding-expelling process improve soybean oil yield?

- To examine the viability of this improved two-stage extruding-expelling process, techno-economic analysis was performed by using SuperPro Designer for simulation of the soybean extruding-expelling process. Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%.

- Is soybean meal a profitable oil extruding process?

- Though the oil expelling process is used to produce oil, the soybean meal is actually the driving force for the whole production system. From Figure 8 a, the increasing economic and markets can be also impacted. The extruding-expelling process has positive gross and net profits, indicating this process was profitable.