crushing cage of soybean oil expeller in congo

- Usage: Soybean Oil

- Type: Soybean Oil Extraction Machine

- Production Capacity: >3TPD

- Voltage: 220V/380V

- Dimension(L*W*H): 1250*530*1140

- Weight: 285kg

- Product name: YZYX90 machine oil press

- Color: Yellow or customized

- Capacity: 1250KGs/h

- Raw material: Soybean Seeds

- oil content of dry cakes: <=7.8%

- spiral axes rotate speed(r/min): 32-42

- Advantage: Simple Operation/high efficiency

- Application: Screw Oil Expeller

- Material: Carbon Steel Q235

- Company character: manufacturer with export right

- Certification: ISO9001: 2008;SGS;TUV

Design and Construction of Oil Expeller Press with Structural

This project work represents the design and construction of an oil expeller press, performance test of it with several raw materials e.g. coconut, rape seed, sesame, sunflower seed and structural

Product description. Kumar X' Press Series Oil Expeller Max 200 is currently the largest in the range with rigorous and high design standards to deliver world class performance and reliability with minimum investment. The series consists of steel cast double chamber expellers with horizontal and vertical feeders, inbuilt oil-n-foots conveyor

Extrusion/Expeller® Pressing as a Means of Processing Green Oils

The experimentation of Nelson et al. in 1987 led to the use of extrusion as a means to pre-treat oilseeds for subsequent full pressing. Coarsely ground soybean was processed through a high-shear extruder producing a hot, foamy mixture of small particles, liberated oil, and vaporizing moisture.

After the soybean is broken, the grain size is uniform, no oil coming out, no agglomeration, little powder, and the particle size meets the requirements. There are several ways to crush oil, such as impact, shear, extrusion and milling. Commonly used crushing equipment is toothed roll crusher, hammer crusher, disc sheller. The broken selection

Expanding and Expelling - AOCS

Expanding and Expelling. Home Edible Oil Processing. Although mechanically the machines used to perform the expanding and the expelling functions share a number of common features, they serve completely different purposes. The expander is a unit assigned to seed or product preparation, whereas the expeller is the machine for mechanical oil

Abstract A minimal residual oil content in the meal coming out of the hexane extractor is a clear benefit for a crushing plant; the more oil yield the better revenue for the crusher. In a modern and ef cient extraction fi plant, a residual oil content 0.5% for soybean meal is expected.

Super Duo Series Expeller® - Anderson International Corp

The Super Duo Series Expeller is ideal for capacities of 10-30 tons per day on difficult-to-process specialty materials such as corn germ, coffee beans, sesame seed, and grapeseed. The unique dual-pressing design allows for the lowest possible residual oil levels in a single pass. Highlights. Features. Applications.

The effect of expeller screw press and pre-treatments on the quality and quantity of soybean oil and cake was studied using a commercial oil expeller. The pretreatments included whole soybean crushing, soy grits crushing, and crushing of soy grits extruded at 135°C. The screw speeds were 28, 35, and 45 rpm.

- How to dehull a soybean?

- Seed preparation and meal treatment block diagram applied to dehulled soybean (Desmet Ballestra Courtesy). common type and is suitable for all types of soybeans. But the other methods. The warm dehulling ( Fig. 4) is the most step. Warm dehulling is an effective means of thorough hull extraction. Warm dehulling is especially applicable when

- What is the Anderson Lion expeller oil press?

- The Anderson Lion Expeller Oil press is designed to continue Anderson¡¯s long-standing tradition of providing the industry with the most durable and efficient mechanical screw presses on the market.

- Can two-stage extruding-expelling process improve soybean oil yield?

- To examine the viability of this improved two-stage extruding-expelling process, techno-economic analysis was performed by using SuperPro Designer for simulation of the soybean extruding-expelling process. Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%.

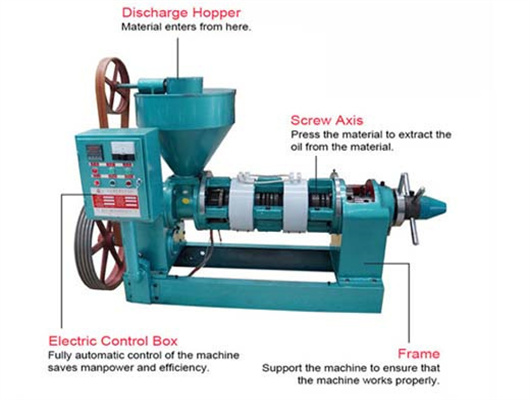

- What is an oil expeller?

- It is followed by the overview of the product which is the oil produced in the market and continued with the overview of the materials of the product by the oil expeller. The Oil Expeller is a screw type machine, which presses oilseeds through a caged barrel-like cavity.