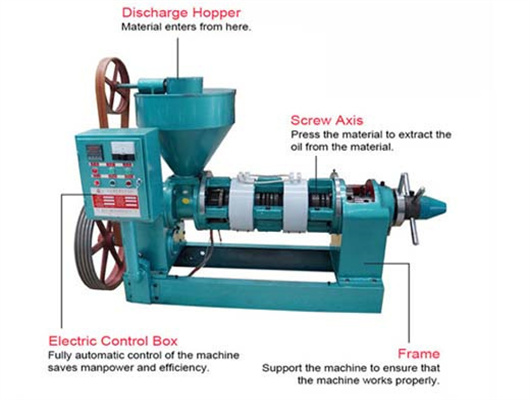

semi- electrical soybean oil expeller in congo

- Usage: oil manufacturing machine

- Type: Soybean Oil Pressing Machine

- Production Capacity: 50-200tpd cooking oil manufacturing

- Voltage: 220V/380V/440V

- Power(W): depend on capacity

- Dimension(L*W*H): 5432*2636*2345

- Weight: 850 KG

- After-sales Service Provided: Overseas service center available

- Keywords: cooking oil manufacturing machine

- Name: cooking oil manufacturing

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business type: manufacturer

- Methods: oil manufacturing machine

- oil rate: 20%-98%

Techno-Economic Analysis of Extruding-Expelling of Soybeans

The oil recovery efficiency was 72% which results in the annual soybean oil productivity. corresponding to these 6 scales are 4.10, 12.81, 25.62, 89.67, 175.56 and 398.67 million kg, respectively

In 1907, the first Expeller® was exported to a Linseed plant in what is now Kranj, Slovenia. Since then, the Anderson Expeller® has processed over 60 different oil and fat bearing seeds, beans, and nuts. Due to the many years of experience working in the field all over the world, our company has developed the expertise to provide the

Design and Construction of Oil Expeller Press with Structural

This project work represents the design and construction of an oil expeller press, performance test of it with several raw materials e.g. coconut, rape seed, sesame, sunflower seed and structural

The new procedure offers potential for producing natural soybean oil and food grade low fat soy flour by a relatively low cost operation. It may be adopted as an improvement to existing conventional expelling operations in less developed countries or as a commercial or on-farm operation for producing value added products from soybeans within the U.S. References 1.

Soybean Oil Production Line Overview - Edible Oil Expeller Machinery

The refined soybean oil is pale yellow, clear, transparent, odorless, and has a good taste. It can be used for cooking without foam and smoke. It is mainly used as cold salad oil in addition to as the cooking, frying oil. And the remaining soya bean cakes are used as animal feed. 2. In Chemical Industry. The Soya lecithin, one of the extracts

The oil extraction by mechanical pressing is the most common method for continuous treatment of oleaginous seeds without solvent. Different types of presses can be used depending on the purpose (expeller, expander, and twin-screw extruder) and on the capacity range (3 kg h−1 to 150 t day−1). At the laboratory scale, many authors have highlighted the effect of operating parameters (screw

Insta-Pro ExPress | Quality Expeller Soybean Meal

Some variables that can be managed to enhance the quality of ExPress (R) soybean meal are: The use of high grade, clean soybeans. Controlling the range of moisture content of raw soybeans (9-11%) Proper maintenance of the equipment and the use of Insta-Pro parts as per the manual. Proper extrusion temperature (310-320 degrees Fahrenheit)

We are a global Manufacturer & Exporter of Soybean Oil Mill Plant. Our offered oil mill machinery & equipment is designed using high quality material and modern technology at our state of the art facility. We undertake turnkey project for the complete Soybean Oil Extraction Plant which can extract Soya Oil, Full Fat Soya Meal, Low Fat Soya Meal

- What is the Anderson Lion expeller oil press?

- The Anderson Lion Expeller Oil press is designed to continue Anderson¡¯s long-standing tradition of providing the industry with the most durable and efficient mechanical screw presses on the market.

- Why is soybean meal important in the mechanical expelling process?

- Through fluctuations in economic conditions, soybean meal plays an important role in earning profits, making the whole mechanical process profitable. According to the sensitivity analysis, the sale of soybean meal is one of the driving forces for the mechanical expelling process, especially in large industrial scales.

- Can two-stage extruding-expelling process improve soybean oil yield?

- To examine the viability of this improved two-stage extruding-expelling process, techno-economic analysis was performed by using SuperPro Designer for simulation of the soybean extruding-expelling process. Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%.

- How profitable is soybean oil & soybean meal?

- Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%. Soybean oil and soybean meal contributed about 25% and 75% of total revenues, respectively. Through fluctuations in economic conditions, soybean meal plays an important role in earning profits, making the whole mechanical process profitable.