low temperature soybean oil expeller in congo

- Usage: Soybean pomace oil

- Type: Soybean pomace oil solvent extraction mill

- Production Capacity: high

- Voltage: 220V, 380V, or other

- Power(W): 11KW

- Dimension(L*W*H): 2300*1650*1600mm

- Weight: 1200 KG

- Certification: BV, CE, ISO9001, etc....

- Solvent consumption: ≤ 2Kg/T (No.6 solvent oil)

- Finished meal moisture: ≤ 13% (adjustable)

- Crude oil moisture and volatile matter: ≤ 0.30%

- Residual oil in meal: ≤ 1%

- color: depend on the requirements of clients

- capacity: based on the need of clients

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Power consumption: ≤ 15KWh/T

- certification: BV, CE, ISO9001, etc....

Understanding Expeller-Pressed Oils in Food Manufacturing

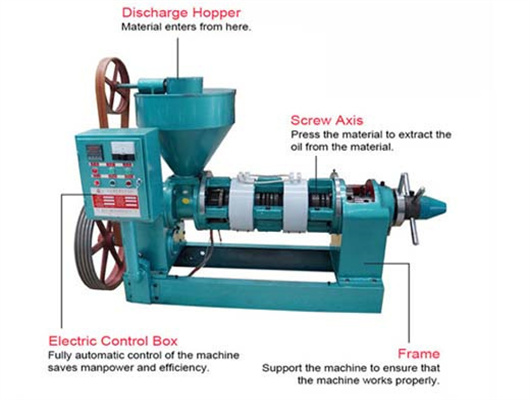

Expeller pressing is the mechanical method for extracting oil from seeds and nuts. It involves crushing the raw material, such as soybeans, sunflower seeds, or olives using a mechanical press without the use of chemicals or excessive heat. Cold-pressed oils are extracted using a similar mechanical process as expeller pressing, but the raw

The effect of expeller screw press and pre-treatments on the quality and quantity of soybean oil and cake was studied using a commercial oil expeller. The pretreatments included whole soybean crushing, soy grits crushing, and crushing of soy grits extruded at 135°C. The screw speeds were 28, 35, and 45 rpm.

Soybean Solvent Extraction Plant

Soybean or soya bean is a legume originated from East Asia and moved to South and North America. It has numerous applications and edible uses. Soya is used to produce edible protein, soya milk, soy sauce, soya bean oil and many other applications. Soya bean is the main ingredient of and resource of protein in feed milling industry.

The negative relationship between protein and oil contents poses a difficult task for the plant breeder who wishes to increase oil content in soybean seed while maintaining a high percentage of protein. Low and high temperatures were associated with a higher protein content (Figure 2a) and less amount of oil (Figure 2b), as exhibited in

Expanding and Expelling - AOCS

Expanding and Expelling. Home Edible Oil Processing. Although mechanically the machines used to perform the expanding and the expelling functions share a number of common features, they serve completely different purposes. The expander is a unit assigned to seed or product preparation, whereas the expeller is the machine for mechanical oil

conducted a performance evaluation test to investigate efficiency of oil expeller machine, the effect of kneading temperature on the oil yield and the extraction losses of the machine. Fakayode and Ajav (2019) developed and evaluated a screw press moringa oil expeller in terms of oil expression efficiency (OEE), material balance efficiency

Formation, characterization, and potential food application

Expeller-pressed corn germ oil was prepared using a low-shear screw oil expeller (Model DD 85 G-1, Komet IBG Monoforts, Mönchengladbach, Germany). This expeller was equipped with an electrical-resistance heating ring attached around the outer surface of the press head and was powered by a 3-kilowatt driver with speed‐control gearbox.

The first stage is mainly to dissolve the oil in the damaged cells by solvent. The extraction amount is large and the time is short (15~30 minutes), and the total oil content can be extracted from 85% to 90%.In the second stage, solvents are needed to penetrate into the unspoiled cells for a long time with low efficiency.

- Can extruding-expelling processing improve soybean production?

- As soybean production increases with a limited number of solvent-extraction plants ( Soy Canada, 2016; USDA, 2021 ), extruding-expelling processing has received great attention as part of an on-farm processing method ( Wang et al., 2008; Kiarie et al., 2020 ).

- How many kcal are in a dry extruded-expelled soybean?

- In conclusion, respective values of DE, ME, and NE are 4,591 kcal/kg, 4,099 kcal/kg, and 3,189 kcal/kg in intact EESBM on a DM basis. It is recommended to use NE values of feedstuffs that are exposed to heat for accurate diet formulation. Keywords: dry extruded-expelled soybean, heat damage, net energy, nitrogen balance, pigs

- What is dry extruded-expelled soybean meal (eesbm)?

- The by-product from the extruded soybeans after oil extraction with an expeller is known as dry extruded-expelled soybean meal ( EESBM ).

- How much moisture does a pre-extruded soybean need?

- Moisture ¨C the moisture level in the pre-extruded soybean can vary widely. New crop beans can be15% to 16% moisture, while old crops can be 7% to 8%. The oil press works best with dryer product, typically 5% moisture or less is desired.