sunflower oil line oil line solvent extraction in uganda

- Usage: Other

- Type: Sunflower seed cake extractor machinery

- Production Capacity: 10-3000TPD

- Model Number: JX-096

- Voltage: 380v /440v or the customer local voltage

- Power(W): According to the capacity of Sunflower seed cake extractor machinery

- Dimension(L*W*H): 1610x615x1260mm of Sunflower seed cake extractor machinery

- Weight: 1050 KG of Sunflower seed cake extractor machinery

- Name: Sunflower seed cake extractor machinery

- Raw material: Sunflower Seed

- Function: Sunflower seed cake extractor machinery

- Feature: oil extractor

- Advantage: Simple Operation

- residual oil ratio: 1%

- Solvent residual after desolventizer: <300ppm

- Distillation range: 68-75℃

- Grades of Sunflower seed oil: one grade,two grade,three grade

- Guide install service: Yes

Sunflower Seed Preparation and Oil Extraction

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed

Characterization of sunflower oils obtained separately by

Oil content (% w/w) extracted from a new line of sunflower seeds rich in phytosterols (IASP-18) and conventional seeds (HA-89) by pressing and subsequent solvent extraction compared to total oil

There is also the case of Goula et al. , who extracted carotenoids from pomegranate peels with sunflower oil and soy oil. Their results demonstrated that combining the use of green solvents with ultrasound successfully extracted 0.620 and 0.670 mg carotenoids/100 g of dry peels using sunflower oil and soy oil, respectively.

Extraction of sunflower oil using ethanol as solvent

The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL). The agitation rate was kept constant in all experiments, being sufficient to maintain a well-mixed fluid and the particles in suspension.

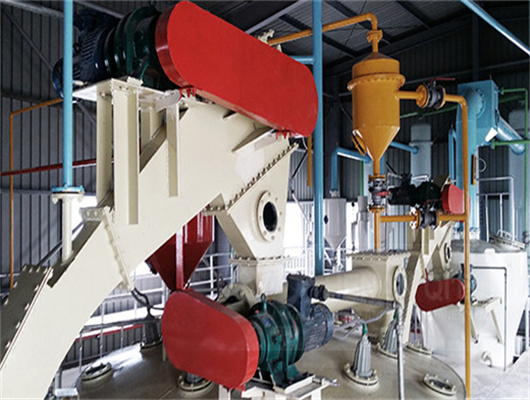

Project Name: Cooking Sunflower Oil Production Line. Project Location: Uganda. Project Capacity: 10 tons per day. Raw Material: Sunflower Seeds, Cottonseeds, Soybeans. Main Equipment: Seeds Pretreatment Equipment, Screw Oil Press Machine, Edible Oil Refinery Plant. Similar Projects: 10TPD Sunflower Oil Processing Plant in Moldova; 10TPD Soybean

Characterization of sunflower oils obtained separately by pressing

In this study we evaluate the chemical composition of sunflower oils obtained separately by pressing and subsequent solvent extraction from a new seeds rich in phytosterols (IASP-18) and conventional seeds (HA-89). Results have shown that the total content of oil was much lower in the IASP-18 (18.1%) than in the conventional (37.5%) seeds.

Sunflower Oil Manufacturing Process Flowchart. GOYUM GROUP provides complete Sunflower Oil Production Line which includes Seed Cleaning, Cracking, Dehulling, Flaking, Cooking/Conditioning, Oil Pressing, Solvent Extraction, Oil Refining Plant. Process Involved in Oil Production Plant to Start Sunflower Oil Manufacturing Business.

- What are the two methods of sunflower oil extraction?

- Common sunflower seed oil extraction processes can be categorized into two methods: expeller pressed sunflower oil and solvent extraction. Next, we will briefly introduce these two methods of sunflower oil production. Sunflower Oil Press & Extraction Machinery for Sale What is expeller pressed sunflower oil?

- What is a prepress solvent extraction method in a sunflower crushing plant?

- In a typical sunflower crushing plant using the prepress solvent extraction method, the initial steps of seed pre-cleaning and seed drying are located in the seed receiving section of the facility, prior to seed storage.

- What is a solvent extraction machine for sunflower oil?

- Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It’s worth noting that solvent extraction machine is costlier.

- How is sunflower crushed for oil recovery?

- Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.