widely used soybean seeds oil extraced expeller in cameroon

- Usage: Soybean Oil, Soybean EDIBLE OIL

- Production Capacity: 20tpd-100%

- Voltage: 380V or 440 V

- Dimension(L*W*H): 1200*1600*1350mm

- Weight: 20000 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Soybean Oil

- Application: Oil Production Line

- Function: Oil Production

- Advantage: Energy Saving

- Keyword: soybean oil production Line

- capacity: 10-1000TPD

- Equipment material: Stainless steel or carbon steel

- Raw materials suitable: Vegetable, Soybean oil cake,Soybean seed,etc

- Oil rate: 45%-60%

- Press type: Hot Press Oil Machine

- Color: Stainless Steel Color

Mechanical Continuous Oil Expression from Oilseeds: A Review

The oil extraction by mechanical pressing is the most common method for continuous treatment of oleaginous seeds without solvent. Different types of presses can be used depending on the purpose (expeller, expander, and twin-screw extruder) and on the capacity range (3 kg h−1 to 150 t day−1). At the laboratory scale, many authors have highlighted the effect of operating parameters (screw

The conventional technology used for oil extraction from oilseeds is by solvent extraction. In solvent extraction, n -hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to solvents. However, usage of hexane as a solvent has lead to several

Design and Construction of Oil Expeller Press with Structural

ariation of Extracted oil with respect to time 94.398%~97.3% for Material Discharge seed, rice, canola, camelina, soybeans, sugar cane Screw expeller is widely used for oil extr action in

Calculations are based on 100 ml of Safflower seed oil. GC-FID analysis of Safflower seed oil extracted by continuous screw press (expeller) was performed and the average molecular weight (MW ave) of the oil was calculated according to the fatty acid profile found in Table 5.

A Review of Methods Used for Seed Oil Extraction

pretreatment is necessary. Basic steps in this process are. dehulling, pod or seed coat removal, winnowing, sorting, cleaning, grinding or milling and preheating ( Ogunniyi, 2006; Yusuf et al

prior to expeller pressing of soybean oil, extracting over 70% of oi l compared to single- step expelling, which yielded 60% [24]. This process has also been used for simultaneous

Nutritive value of expeller/cold-pressed canola meal and pre-pressed

Oil can be extracted from oilseeds by solvent extraction, expeller pressing, or expeller/cold pressing (Lee et al., 2020). Solvent extraction is the most widely used method of oil extraction from oilseed crops in North America ( Cheng et al., 2019 ) and canola is the most widely grown oilseed crop of the Brassic a family ( Unger, 1990 ; Cheng et al., 2019 ; Lee et al., 2020 ).

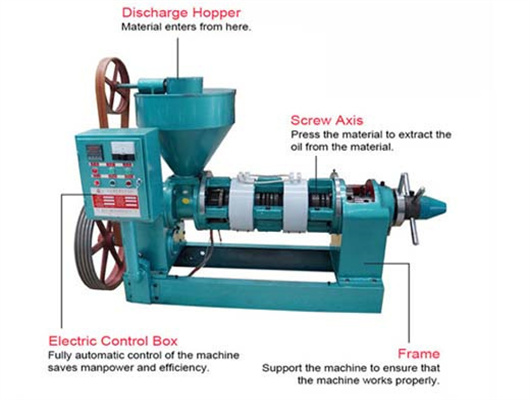

Expanding and Expelling. Home Edible Oil Processing. Although mechanically the machines used to perform the expanding and the expelling functions share a number of common features, they serve completely different purposes. The expander is a unit assigned to seed or product preparation, whereas the expeller is the machine for mechanical oil

- Which seeds are used for oil extraction?

- For oil extraction in particular, it has been applied to a wide variety of seeds such as apricot, canola, soybean, sunflower, grape, acorn and walnut seeds [ 44 ].

- How many tons a year of dried skins and exhausted seed powder?

- Selling the dried skins and exhausted seed 78/ton). The 2100 and 2700 tons/year of dried skins and exhausted seed powder produced, ]. In conclu- an oil extraction process. Co-products were an important piece of the puzzle. of oil extraction processes. For example, a TEA model on soybean oil hexane extraction ]. For the EAEP of soybean oil to be ].

- How to extract oil from oilseeds and oleaginous microbes?

- To harness the potential of oils/fats from oilseeds and OM, development of efficient oil extraction techniques is quintessential. Oil extraction from oilseeds has been carried out widely using solvent extraction, where hexane is used; whereas in oleaginous microbes, widely used solvents are chloroform:methanol.

- Do soybean co-products add value to EAEP extraction?

- (T able 2). During expeller pressing, the solid residue made of ?ber and protein often has residual oil, which adds value to this co-product. When TEA was applied to a two-step ]. Similarly, the importance of soybean co-products on the techno-economic value of EAEP extraction was demonstrated.