high quality crude sunflower oil extractor machine in rwanda

- Usage: pretreatment,extraction,refining, edible oil solvent extraction machine

- Production Capacity: according the capacity

- Model Number: 20--500T/D

- Voltage: 380V or 440 V

- Power(W): according the capacity

- Dimension(L*W*H): according the capacity

- Weight: according the capacity

- Certification: BV and CE

- Processing Types: Sunflower oil production line

- residual oil in cake: 1%

- extractor type: rotocel extractor

- capacity: 20-500TPD

- Equipment material: Stainless steel or carbon steel

- Raw material: Sunflower Seed

- Extractor system: Toasting system

- Use:

- Solvent:

Extracting and refining steps of sunflower oil. | Download

Figure 1 represents schematically the main steps of sunflower oil extraction and refining. There are five main stages where there is a potential leak of minor components: Degumming, neutralization

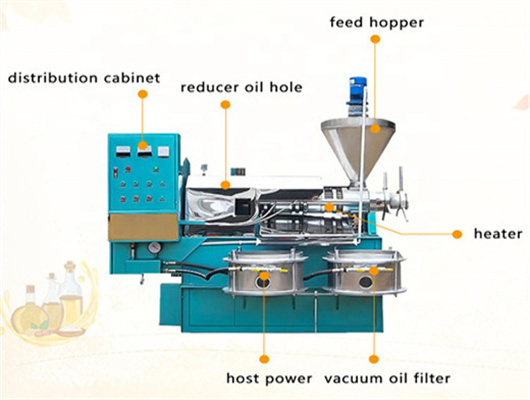

We can supply semi-continuous sunflower oil extraction machine for 2-30T/D and continuous sunflower oil extraction machine for 30-3000T/D. According to the customers requirement we can provide cooking oil press machine, cooking oil pre-press machine, cooking oil solvent extraction machine and cooking oil refinery plant.

Sunflower Oil Production Line - Oil press,oil extraction

The residual oil rate of sunflower seed cake after pressing is about 6%. After pre-pressing, part of the sunflower oil and sunflower seed cake will be obtained. 2, SUNFLOWER SEED CAKE SOLVENT EXTRACTION PROCESS. Sunflower Oil And Cake → Extractor → Solvent Recovery → Steam And Remove Wet Meal → Mixed Oil Treatment → Crude Oil And Meal.

Application range: Oil Crops Seeds; Extraction of Oilseeds: 98% Oil Yield; Buy Rwanda Sunflower Oil Directly From Exporters & Suppliers - Best of 2022 Market Prices. Get Instant Quote. We provide high-quality Rwanda sunflower oil to the local and export markets. We source the raw fresh Rwanda sunflower oil from family growers in the country.

Miscella Distillation Edible Oil Solvent Extraction Machines

3. The crude oil features light color, good quality and low residual solvent because of the low temperature of the steam stripping. 4. Uniform miscella flow to save steam: Ample sized miscella tank to act as a buffer after extractor to insure smooth flow through distillation and therefore minimize second stage evaporator steam Features Of

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier.

Design, fabrication and performance evaluation of centrifugal

Lack of effective machines for dehulling sunflower seeds has resulted in high oil losses during extraction, especially for small- and medium-scale enterprise. This paper reports on the design, fabrication and performance evaluation (in terms of throughput capacity, dehulling efficiency and kernel breakage efficiency) of a centrifugal machine

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on