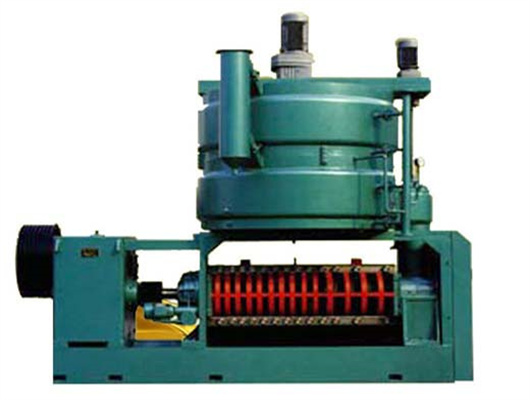

widely used dried soybean oil processing machine in rwanda

- Usage: Soybean oil processing

- Production Capacity: 150-200kg/h Soybean oil press

- Voltage: 380v

- Dimension(L*W*H): 2350x1800x2100mm

- Weight: 1200 KG

- Core Components: Motor, Pump, Gear, Bearing, Engine, Gearbox

- Oil type: Soybean Oil

- Function: pressing vegetable oil

- raw material: Soybean,coca bean

- Advantage: Energy Saving Low Residual

- oil output: 40-60%

- main market: Indonesia,Philippine,Malaysia,Vanuatu,Fiji,Guinea

- Application: edible oil factory

- oil residue in cake: 6-7%

- accessory machines: crusher,roaster,press,filter

- quality: high quiality Soybean oil milling machine

- price: good price Soybean oil milling machine

Soybean processing: what are the main machines used?

We recommend a drying air temperature of 60 °C. This value is preferable because it allows the soybeans to be dried quickly, without sacrificing optimal drying of the same. The lower the drying temperature, the more delicate the treatment. Mecmar ‘s mobile dryers and tower dryers ensure a uniform and efficient soybeans drying process.

Publisher Summary. Soybeans are very important in the world production of oilseeds. Soybean dominance comes from a variety of factors, including favorable agronomic characteristics, reasonable returns to the farmer and processor, high-quality protein meal for animal feed, high-quality edible oil products, and the plentiful, dependable supply of soybeans available at a competitive price.

A Step-by-Step Guide Exploring the Art and Science Behind Soybean Oil

Production of soybeans expanded from the southern part of the United States. 1950-70's. The U.S. accounted for more than 75% of global soybean production. 1970's. Production of soybean started at a large scale in many South American countries. 2003. The share of the U.S. in global soybean production came down to 34%.

Soybean proteins (SPs) possess high nutritional value and numerous functional properties such as emulsification, foamability, gelation, and water and oil-holding capacity. It can be widely used as food supplements, emulsifiers, meat and pharmaceutical products, and infant formula in the food industry [1].

Soybean Oil Processing Byproducts and Their Utilization

Refining of soybean oil, to make a neutral, bland-flavored, and light-colored oil, results in several by-products. The by-products consist of various mixtures of phosphatides, unsaponifiables, glycerides, free fatty acids, and soap. Lecithin contains mostly hydratable phosphatides, together with some free fatty acids and neutral oil (glycerides).

Soybean oil is a widely consumed vegetable oil derived from soybeans, one of the most important oilseed crops worldwide. It is known for its neutral flavor, versatile culinary applications, and nutritional benefits. Soybean oil is extracted from the seeds of the soybean plant through a process of mechanical pressing or solvent extraction.

Soybean Processing Basics: Operations - NOPA

NOPA members produce meal and oil from oilseeds through a solvent extraction process, employing modern technologies to meet food safety and federal permitting requirements and ensure worker safety. Below is a standard flow chart that illustrates the various stages of a soybean as it journeys through a processing plant to become meal and oil.

First in oil with Alfa Laval. Reliable seed oil processing equipment covering all steps of refining for any type of edible seed oil. Oilseed processing solutions for boosting capacity, limiting loss and increasing yield, creating new profitable possibilities. Improved sustainability and reduced operational costs thanks to unique technologies

- What are the by/waste products produced by the soy food processing industry?

- The soymeal, hull, soy-whey, soy flakes, and okara are the main by/waste products produced by the soy food processing industry. These by/waste products are highly nutritious, but due to a lack of cost-effective technology, either it get deposited in the water bodies or used for other industrial purposes.

- How can extrusion technology be used to produce soy-based products?

- Apart from eliminating anti-nutritional factors, extrusion technology can be used to produce soy-based products such as pasta, noodles, soy chunks, meat analog, textured soy protein, ground meat extenders, processed meat, confectionery, and ready-to-eat soy-based snakes (see Fig. 5) ( Friedeck et al., 2003 ).

- What industries use soybeans?

- In the United States, a significant proportion of soybeans is used for the animal feed industry, followed by human food, nutraceutical, and other industrial purposes. Soybean processing industries generate a huge number of by-products during the processing of primary soy-based products.

- Can a zero-waste soybean processing model support a sustainable food system?

- A zero-waste soybean processing model is proposed in this review to support a sustainable food system. 1. Introduction