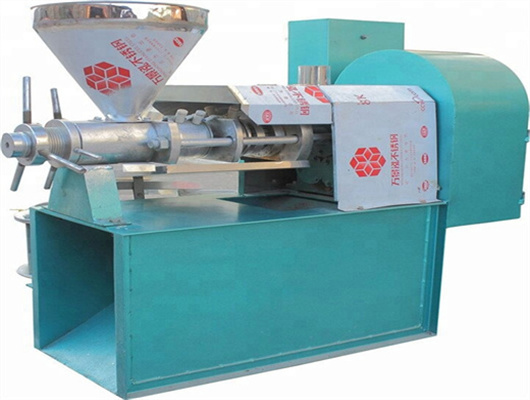

d-peanut seed oil extraction plant in mozambique

- Usage: automatic Peanut oil making machine

- Type: automatic Peanut oil making machine

- Production Capacity: 100 kg/h - 1000kg/h

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): various with capacity

- Weight: changed with capacity

- Certification: CE and ISO

- Raw material: Peanut Seed

- Product: to make crude Peanut oil

- Solvent name: n-hexane

- Capacity: from 5T to 2000Tautomatic Peanut oil making machine

- Oil content in Peanut: about 50%

- Oil residues: less than 1%

- Function: getting Peanut oil from Peanut

- Manufacturing experience: 19 years experience in Peanut oil field

- Material of equipment: stainless steel and carbon steel

Characterization of peanut seed oil of selected varieties

Peanut seeds were dried and converted into powder form to facilitate the oil extraction process by Soxhlet extraction. The powder was stored in polyethylene bags at 4 °C for further study. While whole peanut seeds were used for mechanical oil extraction (pressing method).

Peanut (Arachis hypogaea L.), an important source of high-quality edible oil, is cultivated in more than 100 countries.According to recently published data, more than 41 million tons of peanut pods are produced annually worldwide and China, the world’s largest peanut producer, accounts for 40% of global production (FAOSTAT 2020), but this output is insufficient to meet increasing domestic

Defatting and Defatted Peanuts: A Critical Review on

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

Peanut (Arachis hypogaea) is an important oilseed crop of the world. Peanut seed oil (PSO) contains linolenic acid, oleic acid, also a good source of omega-6 fatty acids and omega-3 fatty acids. It contains an abundant amount of vitamin E which also act as an antioxidant. The research work was carried out to estimate the suitability of utilization of peanut oil from different available peanut

Potential use of peanut by-products in food processing: a

The average production of crush peanut around the world is about 14.09 million metric tons from 2000 to 2010 (FAS-USDA 2011). Peanut meals are well separated from peanut kernel after oil extraction. This separation results in another by-product, peanut pulp. Oil extraction also produces waste water, which can result in the pollution of environment.

The peanut seeds treated by Viscozyme L. at a solid-to-liquid ratio of 1:4 (g/mL) and enzyme concentration of 1.35% at a hydrolysis temperature of 52 °C (90 min), resulted in a yield of peanut protein and oil bodies of around 79% and 48%, respectively. The functional properties, including foam stability, emulsifying activity, emulsifying

Functional Proteins from Biovalorization of Peanut Meal

In countries like India and China, more than half of the produced peanuts (nearly 12–14 MMT) are processed using mechanical pressing or solvent extraction to produce edible oil. The residual matter obtained after oil extraction is called peanut meal, or peanut oilcake, and it contains about 47–55% protein (supplementary information 1).

This chapter contains sections titled: Peanut production, history, and oil extraction Oil uses Composition of groundnut oil Chemical and physical characteristics of groundnut oil Health iss...

- How can a peanut seed extract be destabilized?

- Cream from peanut seed extraction was also destabilized using alkaline protease, achieving a 65% free oil yield. This was a steep increase compared to the cream from the control, which had less than a 5% free oil yield [ 82 ]. Additionally, enzymes can be used to increase protein recovery from the skim layer.

- How is oil extracted from oilseeds?

- Conventional oil extraction from oilseeds has been performed by hydraulic pressing, expeller pressing and solvent extraction (SE) [ 1 ]. Among these methods, solvent extraction has been widely adapted for economical and practical concerns.

- How is peanut oil extracted?

- Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent ( n -hexane) extraction [ 29 ]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

- Is oil extraction from peanuts environmentally friendly and cost-efficient?

- A comparison in terms of productivity, efficacy, specificity, quality of the extracts, and operating conditions was conducted, which favored the novel methods as being mostly environmentally friendly and cost-efficient. Chemical methods of oil extraction from peanuts.