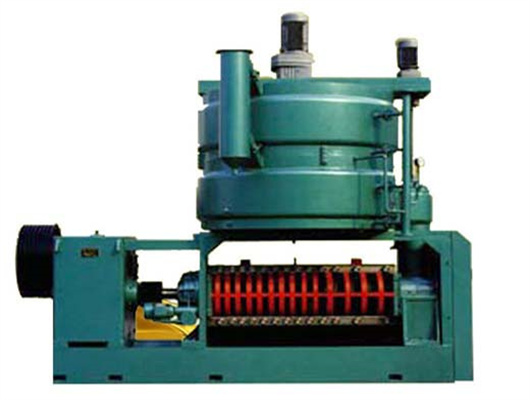

cotton seed soybean oil press processing machine in mozambique

- Usage: Soybean Oil, Cooking Oil

- Type: Soybean Oil Extraction Machine

- Production Capacity: 4-7t/d

- Voltage: 7.5kw/380v

- Dimension(L*W*H): 1860X1700X1780mm

- Weight: 800 KG

- Core Components: Motor, Other, Gear, Bearing, Engine, Gearbox

- Oil type: Soybean Oil

- Raw material: Soybean

- Product name: Oli Press Machine

- Function: Making Edible Oil

- Application: Oil Production Line

- Advantage: Energy Saving Low Residual

- Keyword: Mini Oil Expeller

- Feature: High Oil Yield Efficiency

- Material: Stainess Steel

- Character: Professional Manufactuer

- Press type: Screw Cold Hot Oil Press

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

Flaking: To make cracked Cotton seeds kernel pcs into uniform smaller flakes with thickness ≤ 0.5mm, less powder, non-oil spilled, pinching softly by hand and the ratio of smaller powder than 1mm sieve mesh is ≤ 10% - -15%. Cooking: The process is to add the steam into the crushed/flaked seeds pcs, then to dry the seeds for getting rid off

Cottonseed Oil Cake: the product of cotton seed being extracted the residual oil and can be used as protein in feed production. The complete cotton processing plant has a series of process, including delintering, dehusking, oil pressing, solvent extraction for oil, oil refining and more. Now, it has been a popular for many investors or oil

Complete Equipment and Machinery for Cottonseed Oil Mill Plant

Removing the Hulls. Hulls makeup about 40% to 55% percent of cottonseeds and also has 0.3% to 1% oil. You can get 14% to 25% oil from cottonseed and 30% to 40% oil from the kernels. The hulls also have residue wax, pesticide, brown pigment, and lint, which can compromise the quality of cottonseed products.

NOPA members produce meal and oil from oilseeds through a solvent extraction process, employing modern technologies to meet food safety and federal permitting requirements and ensure worker safety. Below is a standard flow chart that illustrates the various stages of a soybean as it journeys through a processing plant to become meal and oil. View […]

BEST Soybean Oil Machine for Sale|Screw Pressing & Solvent Extraction

The main process is as follows: Preparation or cleaning of the soybean seeds; Pre-pressing: use oil expeller to press oil from the beans through mechanical or physical method. Extract oil from oil cakes by solvent; Purification or refining of the extracted oil; Winterizing and hydrogenation (optional); The complete soybean oil manufacturing

Anderson International Corp, as the inventor of the original continuous mechanical screw press , is recognized as a global leader in the oilseed processing industry for over 135 years. Anderson has designed, manufactured, and commissioned over 12,000 pieces of processing equipment for over 1,000 plant installations in over 100 countries

Automatic Small Screw Soybean Oil Press for Sale with Low Price

Model: YZS-95 Screw oil press. Capacity: 5T per 24Hours. Power: 11KW. Size: 1920*550*765mm. Weight: 480kg. This oil press is widely used to process various kinds of vegetable seeds and nuts, including soybean, peaunt, sunflower seeds, sesame, mustard seeds, castor bean, cotton seed and so on. YZS-95 Screw Oil Press is a type of oil making

In order to process soybean oils from soya beans, soybean oil pressing line is necessary. Soybean Oil Pressing Main Process: Elavating Soybean Seeds Cleaning Cooking Oil Pressing. If you want to get the crude oil, only oil pressing step is ok, if you want to clean the impurity from the oil , oil filter machinery is needed. Of course if you want