high efficiency jatropa seed soybean oil expeller in mozambique

- Usage: Soybean Oil

- Type: Vegetable Oil Processing Equipment

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 1000*600*600mm

- Weight: 450kg

- Warranty: 1 Year, 12 Months Soybean oil mill

- Warranty of core components: 2 years

- Core Components: Motor, Pressure vessel, Pump, Gear, Bearing, Engine, Gearbox

- Raw material: Soybean Oil,etc

- Name: Oil Press

- Function: Making Edible Oil

- Advantage: Energy Saving

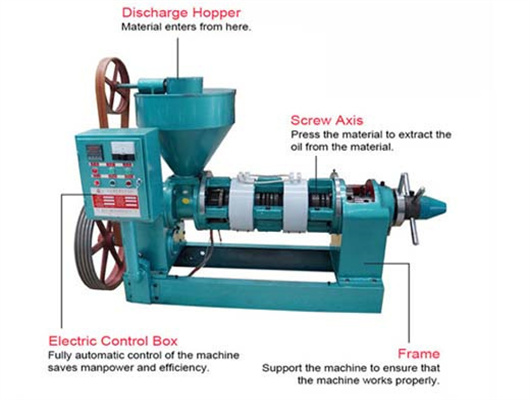

- Application: Screw Oil Expeller

- Product name: Screw Press Oil Expelle

- Material: Stainess Steel Soybean oil mill

- Color: Clients' Requirements Soybean oil mill

- Item: Edible Oil Press Soybean oil mill

- After Warranty Service: Video technical support, Online support, Spare parts

- Local Service Location: Pakistan

- Certification: ISO

Oil expression from Jatropha seeds using a screw press expeller

A maximum oil recovery of 73.14% was obtained when Jatropha seeds were conditioned to a dry basis (db) moisture level of 9.69% and cooked at 110 degrees C for 10 min. Screw press oil recovery

The acid value of oil was found to be 2.24 ± 0.01 mg KOH/g. The scavenging activity of leaf and oil extract was found to be 29.92 ± 4.72 and 19.94 ± 1.39%, respectively. The oil can also be

Optimization of Mechanical Oil Extraction of Jatropha Seeds

Bioresour. Technol. 102: 7169–7172. Makkar HPS and Becker K. 2009. Jatropha curcas, a promising crop for the generationof biodiesel and value-added coproducts. Eur. J. Citation: Yaduvanshi BK, Bhattacharya T K, Patel SK and Kundu K.2019. Optimization of mechanical oil extraction of jatropha seeds from oil expeller.

Oil recovery was found to be dependent on the moisture content of the sample after cooking and the amount of heat treatment given to the sample during cooking. The highest oil recovery of 73.14% was obtained when Jatropha seed was conditioned to 9.69% (db) moisture and cooked at 110 °C for 10 min. Oil recovery from the screw press uncooked.

Flowchart of Process for Jatropha Oil Production | Jatropha

Enquiry Now. Click or drag a file to this area to upload. Jatropha seed processing flow chart shows how the seed is processed to make biodiesel from Seed of the Jatropha. Leading manufacturer of Jatropha oil screw press.

However, if high oil content is not correlated to the seed size, number of seeds, and number of fruits per plant, the oil content remains an overenthusiastic parameter (Singh et al. 2013). It is generally agreed that a seed yield of 4–5 tons/ha is the threshold for commercial viability of Jatropha (Gopinathan and Sudhakaran 2010 ; Li et al

Chapter 16 Jatropha: From Seed to Plant, Seed, Oil, and Beyond

Jatropha (Jatropha curcas L.) is a multipurpose non-edible oil yielding semi-woody perennial tree (Fig. 16.1), originated in Central America (Divakara et al. 2010; DIBER 2017). Presently, it occurs throughout the tropics and sub-tropics (Heller 1996) and adapted to a variety of rainfall and edaphic conditions (Francis.

Diminishing fossil fuel resources, unstable/increasing prices of oil, environmental issues, global warming/climatic shifts, and allied problems have led the world to focus on alternate, environmental friendly, and renewable energy sources. Among many experimental candidates, production of biodiesel from Jatropha curcas L. has gained significant importance. More than 40 countries in the world

- What is the value of seed oil in Jatropha?

- Evidently, the focus of scientific community revolves around seed yield and high oil content in seeds of Jatropha, and any value above 30% w/w for seed oil is generally appreciated (Ginwal et al. 2004; Kaushik et al. 2007; Singh et al. 2013 ).

- Is phorbol ester toxic in Jatropha curcas seed oil?

- Ahmed WA, Salimon J (2009) Phorbol ester as toxic constituents of tropical Jatropha curcas seed oil. Eur J Sci Res 3:429¨C436 Ali N, Kurchania AK, Babel S (2010) Bio-methanization of Jatropha curcas defatted waste. J. Eng Technol Res 2:38¨C43

- How is biodiesel extracted from Jatropha?

- Biodiesel is the main product from Jatropha, which is obtained from the oil derived from its seeds. Oil is typically extracted using cold press or a mechanical expeller. Steam may be used during the process to maximize the recovery. A high-quality oil is one without any free fatty acids (FFA).

- Is jatropha oil a good feedstock for biodiesel?

- Because Jatropha oil is rich in unsaturated fatty acids (up to three-fourths fatty acids in seeds) (Sarin et al. 2007; Maghuly and Laimer 2013 ), it serves as an ideal feedstock for biodiesel in compliance with the international standards (Tiwari et al. 2007 ).