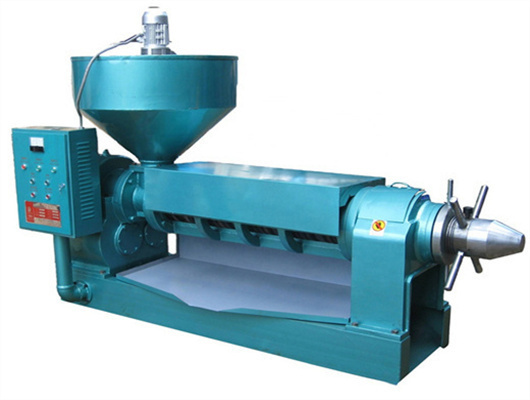

vertical oil press peanut oil mill equipments in malawi

- Usage: different kinds of oil

- Type: Peanut Oil Press Machine

- Production Capacity: 60%

- Voltage: 220V/380V

- Dimension(L*W*H): 1800*1400*2400mm

- Weight: 1100 KG

- Core Components: Motor, PLC, Gear, Bearing, Gearbox

- Oil type: Peanut Oil

- Name: Screw Oil Press Machine

- Raw material: Seeds

- Capacity: 30-500kg/h

- Advantage: High Oil Yield

- Package: Wooden Case

- Application: Peanut

- Color: Customers' Requirements

- Method to press: Screw Squeezed Press

- Keyword: Peanut Oil Processing Machine

- After-sales Service Provided: Free spare parts,Online support,Video technical support

Groundnut Oil Manufacturing Process With Flowchart - Goyum

Step 4: Pressing. The peanuts are transfer by conveyor and fed through the hopper of screw press machine. Continuous transport of material by the screw shaft causes pressure to increase to a level needed, which increases friction inside the screw press and generates heat which lowers viscosity of the oil in the crushed seeds thereby increasing the oil flow rate.

Oil Press Machinery. We Are Distinguished Manufacturer And Service Providers For The Turnkey Solutions To Setup Oil Mills Projects. Right From Designing To Fabrication With Onsite Installation And Commissioning Of Screw Oil Press Machine, Oil Expeller, Oil Processing Machine.

Oil Mill Machinery for Oilseeds Processing Plant

Oil Mill Plant Process. Our Oil Mill Machinery can process various types of oil seeds & nuts such as Soybean / Soya bean, Cottonseed, Groundnut / Peanut / Earthnut, Palm Kernel, Sunflower Seeds, Shea Nut, Mustard Seeds, Copra / Coconut, Sesame Seeds, Cashew Nut Shell, Rapeseed / Canola Seeds, Neem Seed, Niger Seeds, Castor Seeds, Cashew Nut Shells, Corn Germs, Jatropha Seeds, etc.

Peanut Oil Pressing Methods. Generally, the husk content of peanut is 30-35%, and the oil content in peanut kernel is 40-50%. Therefore, the peanut pretreatment processes include cleaning, dehusking and separating of hull & kernels. According to pressing temperature, there are two peanut oil pressing technologies: hot pressing and cold pressing.

Oil Mill Plant, Oil Milling, Edible Oil Mill Plant, Oil Mill Plant

Oil Mill Plant – Oil Milling. With over 30 years of experience, we announce ourselves as leading manufacturers and exporters of oil mill plants and oil mill projects. Due to constant rise and innovation in technology, we have come up with state-of-the-art oil mill machines for the efficient and effective extraction of oil.

GOYUM SCREW PRESS is a leading manufacturer of groundnut / peanut / earthnut oil mill plants. We have exported oil mill machinery and equipment for customers around the world. Our groundnut oil extraction machines are successfully running in India, Nigeria, Tanzania, Chad, Senegal, Cameroon, Ethiopia, Niger, Ghana, Sudan, Mali, Burkina Faso

Supply Professional Oil Milling Plant and Oil Pressing Equipments

Oil Pressing Flowchart. Oil pressing / oil milling often includes thress sections, they are cooking , pressing and filtering. In each process, different oil milling equipment will be used, such as steam cooker, oil press, plate filter press. Advantages of Mechanical Pressing Technology. The speed reducer saves the energy of the equipments

These oil mill can process a number of oilseeds like peanut, soya, cotton seeds sunflower seeds, corn germ, rape seeds, canola, castor, sesame, neem seed, sheanut, palm kernel and the like. The most important equipment in the entire milling / pressing process is oil expellers which are used for high oil content seeds and also used for smaller