peanut oil extraction plant in malawi

- Usage: continuous solvent extraction plant

- Type: continuous solvent extraction plant

- Production Capacity: 50-300TPD

- Voltage: 380V/50HZ

- Power(W): according to capacity

- Dimension(L*W*H): 1200*400*900mm3

- Certification: ISO CE BV

- Name: continuous solvent extraction plant

- Warranty: 1 year

- Application: oil extracted

- Residual oil in meal: less than 1%

- Power consumption: not more than 15KWh/T

- Solvent consumption: less than 2kg/t

- Crude oil moisture and volatile matter: ≤ 0.30%

- Finished meal moisture: ≤ 13% (adjustable)

- Residual solvent in finished meal: ≤300PPM (qualified detonated experiment)

- Steam consumption: ≤ 280KG/T (0.8MPa)

Groundnut Oil Manufacturing Process With Flowchart - Goyum

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

It is mainly used in Chinese, American, and Southeast Asian foods. Unrefined peanut oil is used as a dressing or as a condiment, whereas refined peanut oil can be used to make fried goods in large scale since it is cost-effective (Wang 2016). Peanut oil was one of the first oils to be used to produce biodiesel (Gunstone 2011; Jazie et al. 2012).

by groundnut oil making machine in malawi

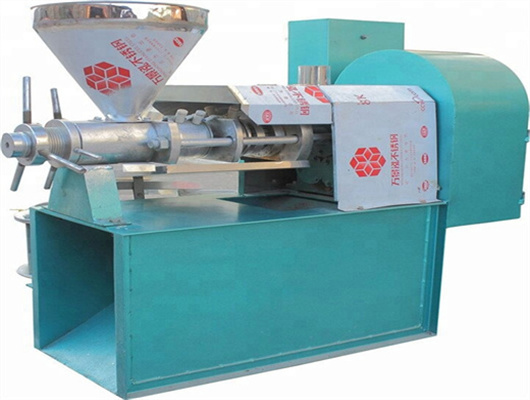

Buy Groundnut Oil Production Machine at Factory Price. Type: Cold & Hot Pressing Machine and Oil Refinery Machine. Production Capacity: 100kg/h-5000kg/h. Voltage: 380. Dimension (L*W*H): 2900*1850*3240. Weight: 5000KG. Key Selling Points: Automatic. Cost of Groundnut O il Production Machine: $5000~$15000 (Reference Price); The investment in

Groundnut Decorticator. Groundnut decorticator machine is used to remove the hard shell of peanuts and get red skin peanut kernels automatically. The shelled peanut kernel can be applied to the peanut oil production line. Groundnut decorticator is versatile in shelling not only peanuts but other oil seeds like almonds, sunflower seeds.

Groundnut (Peanut) (Arachis hypogaea)

The peanut plant (Arachis hypogaea) belongs to the legume family and is grown as an ornamental plant in South America. Groundnut is used for various purposes including oil extraction. The oil

In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization.

Peanut Oil Processing Technology

The peanut oil produced with the leaching method is generally needed to be brought to the refinery workshop for refining treatment before being canned and packaged. 1. Leaching Procedure. The leaching procedure mainly makes use of the solid-liquid extraction principle to select certain fat-dissolving organic solvents to extract the peanut oil.

Depending on the variety and other cultivation details, peanut kernels contain between 45 to 55% oil, with the Spanish variety typically boasting the highest oil content. While many peanut oil mills rely on the traditional double press method, some plants are turning to high-shear dry extrusion to streamline the process.

- How can aqueous enzymatic extraction improve the function of Peanut proteins?

- Discuss extraction methods, modifications and applications of peanut proteins. Aqueous enzymatic extraction can efficiently separate oils and peanut proteins. The functionality of peanut proteins was significantly improved after modification. Native and modified peanut proteins can be used for a variety of purposes in foods.

- How to make peanut oil from groundnuts?

- According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking Step 4: Pressing Step 5: Filtration After harvesting groundnut are received at processing facilities.

- How is peanut oil extracted?

- Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent ( n -hexane) extraction [ 29 ]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

- Is oil extraction from peanuts environmentally friendly and cost-efficient?

- A comparison in terms of productivity, efficacy, specificity, quality of the extracts, and operating conditions was conducted, which favored the novel methods as being mostly environmentally friendly and cost-efficient. Chemical methods of oil extraction from peanuts.