supplier crude peanut oil extraction plant in botswana

- Usage: organic cold pressed Peanut oil

- Type: organic cold pressed Peanut oil

- Production Capacity: 100%organic cold pressed Peanut oil

- Voltage: 220V/380V/440V

- Power(W): 10-50kw

- Dimension(L*W*H): 1200*400*900mm3

- Weight: According to processing capacity

- Certification: CE ISO BV SGS

- Item: Organic cold pressed Peanut oil

- Raw material: Peanut Seed

- Steam pressure: ≥1.2MPa

- Voltatile substance in crude oil: ≤0.3%

- Steam consumption in refining: ≤280kg/ton of oil

- Oil residue in waste clay: ≤25% of waste clay

- Solvent contain in crude oil: ≤200ppm

- Oil residue in meal: <1%

- Warranty: 2years

- Feature: High Oil Yield Efficiency

Groundnut Oil Manufacturing Process With Flowchart - Goyum

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

2) Peanut oil solvent extraction workshop: After the pre-treatment, the next step is solvent extraction, which is using the solvent to exact oil from the peanut cakes. By this kind of technology, the residual oil ratio in the oil meal is less than 1%. Peanut oil solvent extraction plant and working process flow chart. 3) Peanut oil refinery plant:

Peanut proteins: Extraction, modifications, and applications: A

The yield of free oil extracted from roasted peanut (150 °C, 20 min) using the AEP method was around 92.2% using the optimized processing conditions: solids-to-liquid ratio = 1:5; pH = 9; temperature = 60 °C, and time = 2 h [33]. Liu et al. (2020) investigated a combination of AEP and membrane separation for peanut protein extraction.

Also, some of the seed oils extracted from the plants, such as cotton oil, peanut oil, palm fruit oil, soybean oil, sun flower oil, pomegranate peel oil, rice brane oil, are natural sources whose extracted oil has shown promising results in several fields as in stabilizing emulsion, health beneficial effects, antiatherogenic, anticancer, antihypertensive, and used for modern medicine instead

Bioactive Phytochemicals from Peanut Oil Processing By-products - Springer

2 Chemical Composition and Bioactive Compounds of Extracts from Peanut Oil-Processing By-Products. The edible kernel comprised about 68–72% of the peanut, while the balance 28–32% is the peanut hull [ 8 ]. Peanut kernel’s average thickness, width, and length are 6.9 mm, 3.6 mm, and 8.5 mm, respectively [ 9 ].

View All News. BOL was established in order to achieve the Botswana Government’s broader economic objectives of ensuring security of fuel supply and facilitating active citizen involvement in the petroleum industry. As the National Oil Company of Botswana, BOL serves as the Government’s transformation agent charged with this important

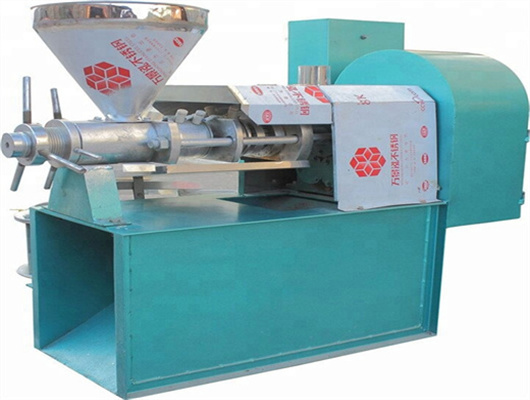

Groundnut Oil Extraction Plant | Peanut Oil Processing | Oil Press Machine

Groundnut Decorticator. Groundnut decorticator machine is used to remove the hard shell of peanuts and get red skin peanut kernels automatically. The shelled peanut kernel can be applied to the peanut oil production line. Groundnut decorticator is versatile in shelling not only peanuts but other oil seeds like almonds, sunflower seeds.

Vegetable oil has been the backbone of Agri International for more than 20 years. We source our oils from the heart of the USA and also have strong relationships with major crushing mills overseas. We specialize in liquid bulk logistics and movement of oils and fats with a vast network of rail, intermodal, drayage and ocean carriers to deliver

- Why do we dehull peanut oil before oil pressing?

- The purpose of dehulling before oil pressing is to reduce the absorption of oil by the shell, increase the yield of oil, improve the processing efficiency of the peanut oil processing machine and reduce equipment wear and tear. This oil can also improve cake quality and added value.

- How to make peanut oil from groundnuts?

- According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking Step 4: Pressing Step 5: Filtration After harvesting groundnut are received at processing facilities.

- How is peanut oil extracted?

- Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking

- What is groundnut oil manufacturing process?

- Groundnut oil manufacturing process is divided into two methods, the first is mechanical pressing and the second is solvent extraction. Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method.