peanut oil pressing plant ce in lusaka

- Usage: Peanut Oil, Peanut EDIBLE OIL

- Production Capacity: 1-100TON per day

- Voltage: 380V/415V 3 phase

- Dimension(L*W*H): 2000*1500*800mm

- Weight: 1500kg

- Core Components: Motor, Engine

- Oil type: Peanut Oil

- Item: Peanut oil making machine

- Model type: Peanut oil production line

- Steel type: Mild steel and SS

- Main market: Philippine, Ghana, Nigeria, South Africa

- Raw materials: peanut

- Final product: Refined oil

- Production period: 45 days

- Installation period: 60 days

- Advantage: Factory directly sale

- After Warranty Service: Video technical support, Online support, Field maintenance and repair service

- Local Service Location: Nigeria

- Certification: CE & ISO

Production, Processing, and Food Uses of Peanut Oilseed, Oil

In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization.

2.05 –3.63 times higher than that in peanut meal after cold pressing of the oil, except for azoxystrobin having a slightly lower. residue in peanut oil, with 0.92 times that in peanut meal. The

Peanut oil press and peanut oil pressing technology - Oil

The single pressing method is used in peanut oil pressing to extract oil from the kernels. The actual compression ratio of pressed material is 4-4.5, which is larger than soybean obviously, so the compression ratio should be 10 or so when using the screw oil press. The oil discharge gap of the press cage should be broadened and lengthened

The flaking mill is outfitted with a powerful reversible magnet, making it easy to remove impurities attached to the magnet. 4. Cooking, Peanut Oil Pressing:. Major Devices: feeding conveyor, vertical cooker, oil pressing. 5. Cooling:. Major Devices: feeding conveyor, Air Lock Valve, counterflow cooler.

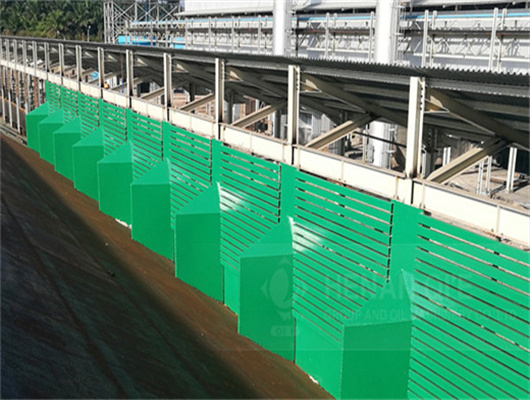

Oil Press Plant - QI'E Group - qiemach

Oil Press Plant. The whole edible oil pressing line contains pre-treatment process and press process, Using magnetic separator, weighing scale and screener to remove impurities of the seeds. Crushing the oilseeds to ensure good softening and flaking effect. Production Capacity: 30-1000TPD.

The conditioned peanut kernels are transported by a conveyor to the twin-screw press for cold pressing; the cold-pressed crude oil and cold-pressed peanut meal with low denaturation will be obtained. After the cold-pressed crude oil is filtered with frame filter, product oil is obtained, which will be packaged by a filling machine to form cold

Explore the peanut press machine's role in oil yield | Duyvis

Peanut press machines, like those manufactured by Royal Duyvis Wiener, are the heart of peanut oil production. The process begins with raw materials, primarily peanut kernels. These are fed into the peanut press machine via a feed inlet, and the magic starts to happen. The machine applies pressure on the peanuts, resulting in oil being extracted.

2 Chemical Composition and Bioactive Compounds of Extracts from Peanut Oil-Processing By-Products. The edible kernel comprised about 68–72% of the peanut, while the balance 28–32% is the peanut hull [ 8 ]. Peanut kernel’s average thickness, width, and length are 6.9 mm, 3.6 mm, and 8.5 mm, respectively [ 9 ].

- What is peanut oil processing technology?

- This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology.

- What equipment is used for cold pressing of peanut oil?

- Figure 3.8. Flow chart of equipment for cold pressing of peanut oil. 2. First, a sheller is used to shell the peanuts, and then the peanut kernels are transported to the low-temperature drying oven to be dried after being subjected to precleaning, gravity/magnetic separation de-stoner cleaning, and grading.

- How to make peanut oil in China?

- Currently, there are two pressing methods: high-temperature pressing and cold pressing. More than 90% of oil production in China adopts the traditional technique of high-temperature pressing, and the peanut oil produced with this method has a strong fragrant flavor and is therefore greatly favored by consumers.

- How is cold pressed peanut oil made?

- After the cold-pressed crude oil is filtered with frame filter, product oil is obtained, which will be packaged by a filling machine to form cold-pressed peanut oil products ( Fig. 3.8 ). Figure 3.8. Flow chart of equipment for cold pressing of peanut oil. 2.