sunflower oil extractor extractor in lesotho

- Usage: Sunflower Oil, Sunflower oil, flaxseed oil, vegetable cooking oil

- Production Capacity: 6 TPD

- Voltage: 380V/50HZ

- Dimension(L*W*H): 1970*700*780mm

- Weight: 680kg

- Warranty: 1 Year, 12 Months

- Color: Optional

- Price: Factory low price

- Delivery time: 30 days

- Quality: High-quality smooth flaxseed oil press

- Feature: Multifunction high efficient

- Advantage: Auto-warming-up Sunflower Oil press machine

- Accessory: Sufficient and reliable spare parts available

- Raw material: Sunflower , flaxseed, sunflower seed, Sunflower

- Certification: CE ISO Sunflower oil press

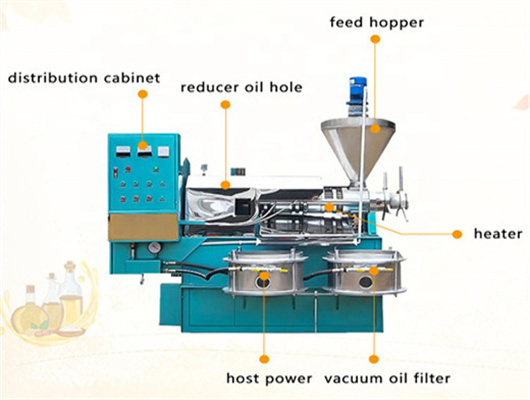

commercial sunflower seed oil extraction machine in Lesotho

Automatic Mini Oil Extraction Machine, Rs 22000 /unit. We "Shreeja Health Care Products" have gained success in the market by Manufacturer and Wholesaler a remarkable gamut of Oil Extraction Machine, Oil Maker Machine, Commercial Oil Press, Mini Oil Ghani Machinery, Filter Press Machine, Oil Ghani Machine etc.We are a well-known and reliable

In this article, the enzymatic aqueous extraction (EAE) of sunflower seed oil was investigated. The effects of the operational variables (temperature, water seed mass ratio, and enzyme concentration) were evaluated in order to define the conditions that maximize the free oil yield (FOY).

Sunflower Seed Preparation and Oil Extraction

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on

However, Soxhlet-extracted sunflower oil content of α-linolenic (18:3) and arachidic (20:0) acids were significantly higher than in other sunflower oils (p < 0.05).The higher content of such fatty acids may result from the method’s extraction time and constant contact between sample and new portions of extraction solvent (Ribeiro et al. 2019; Tanamati et al. 2011; Brum and Arruda 2009).

From Seed to Oil: Unveiling the Sunflower Oil Extraction Process

The process of extracting sunflower oil involves various steps, such as: cleaning. dehulling. cooking. pressing. refining. The extraction method used depends on the desired quality and yield of the oil: Mechanical pressing is a popular method that involves squeezing the seeds using a machine to extract the oil.

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning.

The sunflower seeds oil extraction: the mechanism and kinetics

The kinetics and mechanism of the extraction process investigated. It is shown that the process of extracting sunflower seed oil is complicated and include as intra-diffusion and outer-diffusion oil transfer is similar to extraction of target components from other seeds of plant material (amaranth, rapeseed, etc.).

The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL). The agitation rate was kept constant in all experiments, being sufficient to maintain a well-mixed fluid and the particles in suspension.

- How does a sunflower extractor recover the solvent pumped to the extractor?

- The solvent evaporated from the sunflower meal and the miscella are both recovered in the solvent recovery system within the solvent extraction process area. A typical sunflower plant will recover 99.8¨C99.9% of the solvent pumped to the extractor.

- How is sunflower crushed for oil recovery?

- Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

- Which extraction method is best for sunflower seeds?

- Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

- What is a prepress solvent extraction method in a sunflower crushing plant?

- In a typical sunflower crushing plant using the prepress solvent extraction method, the initial steps of seed pre-cleaning and seed drying are located in the seed receiving section of the facility, prior to seed storage.