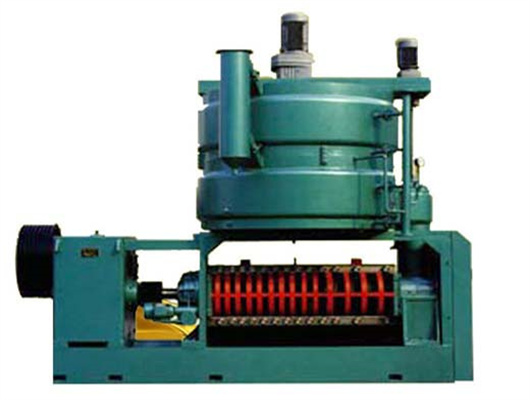

fast rotate disc soybean oil processing machine in lesotho

- Usage: cold pressed Soybean Oil

- Type: cold pressed Soybean Oil

- Production Capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Power(W): 10-50kw

- Dimension(L*W*H): 1200*400*900mm3

- Weight: According to processing capacity

- Certification: CE ISO BV SGS

- Item: Cold pressed Soybean Oil

- Raw material: Soybean Seed

- Steam pressure: ≥1.2MPa

- Voltatile substance in crude oil: ≤0.3%

- Steam consumption in refining: ≤280kg/ton of oil

- Oil residue in waste clay: ≤25% of waste clay

- Solvent contain in crude oil: ≤200ppm

- Oil residue in meal: <1%

- Warranty: 2years

- Feature: High Oil Yield Efficiency

Soybean Oil Extraction Machine

Soybean oil is a widely consumed vegetable oil derived from soybeans, one of the most important oilseed crops worldwide. It is known for its neutral flavor, versatile culinary applications, and nutritional benefits. Soybean oil is extracted from the seeds of the soybean plant through a process of mechanical pressing or solvent extraction.

The first technological phase (phase 1) in soybean processing refers to the manipulation and storage of grain until processing. Within this phase, there are the following technological operations: grain reception, grain cleaning, grain drying, and grain storage. The second technological phase (phase 2) is the phase of soybean processing, within

Seed oil processing | Soybean oil processing | Alfa Laval

First in oil with Alfa Laval. Reliable seed oil processing equipment covering all steps of refining for any type of edible seed oil. Oilseed processing solutions for boosting capacity, limiting loss and increasing yield, creating new profitable possibilities. Improved sustainability and reduced operational costs thanks to unique technologies

Publisher Summary. Soybeans are very important in the world production of oilseeds. Soybean dominance comes from a variety of factors, including favorable agronomic characteristics, reasonable returns to the farmer and processor, high-quality protein meal for animal feed, high-quality edible oil products, and the plentiful, dependable supply of soybeans available at a competitive price.

SOYBEAN PROCESSING FLOWCHART - NOPA

NOTE: The National Oilseed Processors Association (NOPA) represents the U.S. soybean, canola, axseed, sun ower seed and sa ower seed crushing industries. This owchart is an illustrative diagram of standardized steps employed in the processing of soybeans. The steps employed may vary from plant to plant and from oilseed to oilseed. SOYBEAN

The Journal of Food Process Engineering is devoted to the engineering aspects of food processing, providing a vital source for food, agricultural, biological, & chemical engineers. Abstract Soybean oil (SO) was deacidified by liquid–liquid extraction (LLE) in a perforated rotating disc column using ethanol as solvent.

Soybean Oil Processing Byproducts and Their Utilization

Refining of soybean oil, to make a neutral, bland-flavored, and light-colored oil, results in several by-products. The by-products consist of various mixtures of phosphatides, unsaponifiables, glycerides, free fatty acids, and soap. Lecithin contains mostly hydratable phosphatides, together with some free fatty acids and neutral oil (glycerides).

NOPA members produce meal and oil from oilseeds through a solvent extraction process, employing modern technologies to meet food safety and federal permitting requirements and ensure worker safety. Below is a standard flow chart that illustrates the various stages of a soybean as it journeys through a processing plant to become meal and oil.

- What are the technological operations in soybean processing?

- Within this phase, there are the following technological operations: grain reception, grain cleaning, grain drying, and grain storage. The second technological phase (phase 2) is the phase of soybean processing, within which there are technological operations that differ depending on the final product.

- What is the first phase in the production of defatted soybean flakes?

- The first phase in the process of production of defatted soybean flakes can be defined as a successive series of several technological operations characteristic for the preparation plant.

- What is the first technological phase in soybean processing?

- The first technological phase (phase 1) in soybean processing refers to the manipulation and storage of grain until processing. Within this phase, there are the following technological operations: grain reception, grain cleaning, grain drying, and grain storage.

- What are the technological operations in the production of defatted soybean flakes?

- As it has already been mentioned, within this stage in the production of defatted soybean flakes, we have a number of preparatory technological operations. These technological operations are: cleaning, weighting, drying, cracking/crumbling and dehulling, conditioning, flaking.