new design soybean oil expeller in lesotho

- Usage: cumin seed oil extraction machine

- Production Capacity: 1-100T/DAY

- Voltage: 220v

- Dimension(L*W*H): 560*250*280

- Weight: 35kg

- Warranty: 1 Year, 1year

- Core Components: Gear, Bearing, Gearbox

- Oil type: Soybean Oil

- Application: Family

- Color: green

- Advantage: Easy Operation

- Capacity: 1000kg/hour

- Function: Cold Press

- Product name: small oil expeller price in pakistan Soybean oil milling machine

- Raw material: oil crops

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: Egypt, Turkey, United Kingdom, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Russia, Spain, Thailand, Japan, Australia, Kenya, Argentina, South Korea, Chile, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Nigeria, Uzbekistan

- Certification: ISO

Turnkey Soybean Oil Processing Project Installed In Africa

This is a turnkey soybean oil mill plant established in Africa for one of our customer, and this unit consists mainly of oil expeller, oil filtering equipment, cooking kettle, cleaning equipment, etc. It is a turnkey project with a raw material extraction capacity of 50 tonnes per day. If you are interested in starting your own soya bean oil

Specifically, Anderson’s Solvex reduces the amount of solvent for recovery by 40% in the marc and 20% in the miscella. Transform poor quality flakes. The expander can transform low-quality flakes into easily extracted collets, allowing operators to decrease the demands on flaking rolls. The rolls can run at a higher capacity, consume less

Development and Performance Evaluation of an Optimized Screw

Figure 2: Black box analysis for domestic oil expeller . The component hierarchy of domestic oil expeller is given below according to the consisting units for the product: Figure 3: Component hierarchy for domestic oil expeller . Functional decomposition was carried out for individual units of the product. Functional decomposition for heating

This project work represents the design and construction of an oil expeller press, performance test of it with several raw materials e.g. coconut, rape seed, sesame, sunflower seed and structural

Home - Anderson International Corp

Complete systems for oilseed, synthetic rubber, and animal feed processing. Put Anderson’s 135 years of engineering and installation experience to work for you when it comes time to design a new processing system or make changes to existing installations. Anderson has been a global leader for more than 135 years.

Along with maintenance- and operator-friendly packages, the systems can press over 300 metric tons per day (MTPD) in a single machine with residuals as low as 5% when paired with Anderson’s extrusion technology. With minimal modifications, the Anderson Lion Expeller oil press can change from one oilseed application to another, allowing for

Design, development and testing of a screw press expeller

Design, development and testing of a screw press expeller for palm kernel and soybean oil extraction. @inproceedings{Olaniyan2012DesignDA, title={Design, development and testing of a screw press expeller for palm kernel and soybean oil extraction.}, author={A. M. Olaniyan and K. A. Yusuf and Abdul Wahab and Kunle Afolayan}, year={2012}, url

Product Description. Our Company produce complete sets of equipment, oil extraction, processing capacity of up to 15 tons day -1 000 tons, based on years of production experience in the technical parameters have been improved, and the country has been updated compared to the same industry, more advanced process, by majority users.

- Can a mechanical oil expeller press be used for small scale oil extraction?

- A mechanical oil expeller press was designed, constructed & further analyzed with simulation software (ANSYS) in this research work. This expeller can be useful for small scale oil extraction. ASME shaft design code was used in designing the screw shaft of the press. Locally available material (mild steel) was used in manufacturing of the expeller.

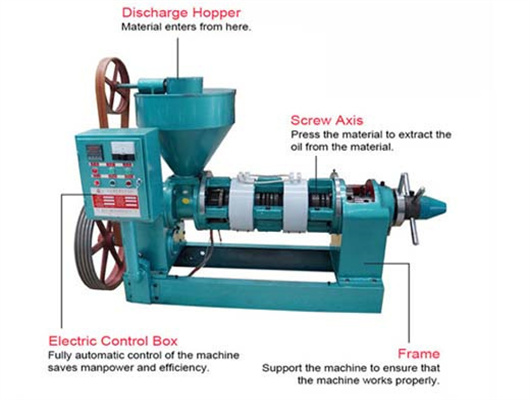

- How does a oil expeller work?

- Locally available material (mild steel) was used in manufacturing of the expeller. A 20 hp 3-phase electric motor was used for running the machine and the rpm of the screw was maintained 140 rpm. A screw rotates inside the barrel of the press which creates pressure for the extraction of oil.

- Can two-stage extruding-expelling process improve soybean oil yield?

- To examine the viability of this improved two-stage extruding-expelling process, techno-economic analysis was performed by using SuperPro Designer for simulation of the soybean extruding-expelling process. Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%.

- What is the efficiency & capacity of oil expeller?

- The expeller has an efficiency & capacity ranging between 68.2% and 85.22 gm/min~98.52 gm/min respectively. ariation of Extracted oil with respect to time 94.398%~97.3% for Material Discharge Efficiency (MDE), 85.22 gm/min~98.52 gm/min for Machine Capacity (MCP).