farm plant peanut oil pressing plant in kenya

- Model Number:YZYX120WZ

- Type: Spiral Sunfower Oil Press

- Appearance: Uniaxial

- Press Materials: Peanut

- Customized: Non-Customized

- Product Name: Peanut Oil Extraction Machine with Filters

- Color: Any Color You Like

- Port: Shanghai, Chongqing, Guangzhou, etc

- Automatic Grade: Semi-Automatic

- Applicable Oil Plants: Other Oil Seeds, Such as, Peanut

- Advantages: High Capacity, Easy Operation

- Wearing Parts: Squeeze Bars, Squeeze Spiral, Squeeze Loop

- Delivery Time: 7~30days Once Order Confirmed

- Transport Package: Wooden Box

- Specification: certificated: ISO, BV, SGS

- Production Capacity: 400pieces/Month

Groundnuts Farming in Kenya (Peanuts) - Imagine Care

With groundnuts retailing at Sh12,000 per 100kilos, one is likely to earn a whopping Sh192,000 in just 90 days. In 2019 the export market price for Kenya peanut (groundnuts) price was $1.96 per kilo. The crop requires less maintenance and adds valuable nitrogen to soils if compared to maize which can earn a farmer less than 40 bags weighing

Peanut oil is considered as a premium edible oil and commands a high price in both US and European markets. In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United

GROUNDNUT FARMING IN KENYA (and AFRICA) - Agri4Africa

The groundnut plant can be erect or prostrate (20–60 cm tall or more) with a well-developed taproot and many lateral roots and nodules. Plants develop three major stems, i.e. two stems from the cotyledonary axillary buds equal in size to the central stem during early growth. READ MORE . Groundnut Farming in Nigeria: Step-by-Step Guide. READ MORE

San Donato Milanese (Milan), 18 July 2022 – Eni completed the construction of the oilseed collection and pressing plant (agri-hub) in Makueni, Kenya, and started production of the first vegetable oil for bio-refineries. The first agri-hub will have an installed capacity of 15,000 tons with an expected production of 2,500 tons in 2022.

Groundnut Oil Manufacturing Process With Flowchart - Goyum

Step 4: Pressing. The peanuts are transfer by conveyor and fed through the hopper of screw press machine. Continuous transport of material by the screw shaft causes pressure to increase to a level needed, which increases friction inside the screw press and generates heat which lowers viscosity of the oil in the crushed seeds thereby increasing the oil flow rate.

By tpz December 9, 2022. Groundnuts, also known as peanuts, are an important cash crop in Kenya. They belong to the legume family and are grown for their edible seeds that have a high protein content. Groundnuts can be used for oil or as a food ingredient. They are commonly roasted and eaten as a snack or used to make peanut butter.

Bioactive Phytochemicals from Peanut Oil Processing By-products - Springer

2 Chemical Composition and Bioactive Compounds of Extracts from Peanut Oil-Processing By-Products. The edible kernel comprised about 68–72% of the peanut, while the balance 28–32% is the peanut hull [ 8 ]. Peanut kernel’s average thickness, width, and length are 6.9 mm, 3.6 mm, and 8.5 mm, respectively [ 9 ].

Sowing seeds to a depth of 5-8 cm at a seed rate of 40-50 kg per ha is recommended depending on seed size. Germination is dependent on the moisture availability, air circulation, soil structure and light. Groundnuts have two main types namely:-. Bunch type e.g. Red Valentia maturing within 90 – 100 days.

- How is peanut oil processed?

- Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization. The food uses of peanut oil and protein are reviewed in this article. Abstract This article reviews the production, processing, and food uses of peanut oil and protein.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- Where is the first vegetable oil produced in Kenya?

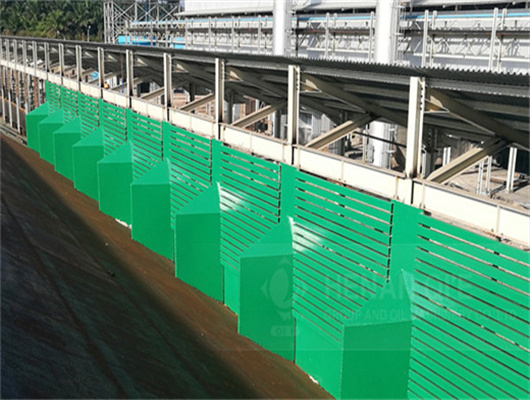

- A worker at the Eni oilseed collection and pressing plant (agri-hub) in Makueni, Kenya. Italian multinational oil and gas company Eni, has started production of the first vegetable oil for bio-refineries in Kenya. Through its subsidiary Eni Kenya, the company set up an oilseed collection and pressing plant (agri-hub) in Makueni early this year.

- How to make peanut oil in China?

- Currently, there are two pressing methods: high-temperature pressing and cold pressing. More than 90% of oil production in China adopts the traditional technique of high-temperature pressing, and the peanut oil produced with this method has a strong fragrant flavor and is therefore greatly favored by consumers.