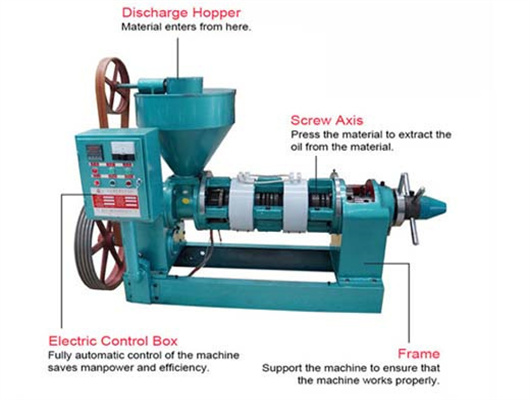

soybean seed crushing oil expeller in botswana

- Usage: locally made sterilizer for Soybean oil

- Type: locally made sterilizer for Soybean oil

- Production Capacity: 1-100TPH

- Voltage: 220V/380V

- Power(W): 18.5KW

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 15TONS

- Certification: ISO CE BV SGS

- equipment mame: locally made sterilizer for Soybean oil

- Raw material: Soybean Seed

- markets available: Africa, America, Asia

- rsidual: less than 0.6%

- warranty: 1 year

- Function: making Soybean oil

- shipping: supplied

- insurance: supplied

- advantage: lower costs, energy saving

- technology: latest

Oilseed Products - Anderson International Corp

Anderson International Corp, as the inventor of the original continuous mechanical screw press , is recognized as a global leader in the oilseed processing industry for over 135 years. Anderson has designed, manufactured, and commissioned over 12,000 pieces of processing equipment for over 1,000 plant installations in over 100 countries

Expeller pressing is the mechanical method for extracting oil from seeds and nuts. It involves crushing the raw material, such as soybeans, sunflower seeds, or olives using a mechanical press without the use of chemicals or excessive heat. Cold-pressed oils are extracted using a similar mechanical process as expeller pressing, but the raw

Maximizing Crush Margins in Oilseed Processing

Seed preparation and pretreating. Processing methods and equipment. Generally, processors can recover about 18% of the oil from soybeans by weight, while producing around 75-80% soybean meal. Using these percentages, the basic crush margin formula for soybeans would be: (oil price x 0.18) + (meal price x 0.80) – oilseed cost = crush margin.

These oil extraction machines gather vegetable oil from oil-bearing seeds and nuts for food and industrial uses, including biodiesel and other fuels. Our durable, heavy-duty oilseed equipment has an average life span of 60-70 years, operating with maximum productivity and lower processing cost per ton. Download our literature on screw presses

Mechanical Continuous Oil Expression from Oilseeds: A Review

The oil extraction by mechanical pressing is the most common method for continuous treatment of oleaginous seeds without solvent. Different types of presses can be used depending on the purpose (expeller, expander, and twin-screw extruder) and on the capacity range (3 kg h−1 to 150 t day−1). At the laboratory scale, many authors have highlighted the effect of operating parameters (screw

Along with maintenance- and operator-friendly packages, the systems can press over 300 metric tons per day (MTPD) in a single machine with residuals as low as 5% when paired with Anderson’s extrusion technology. With minimal modifications, the Anderson Lion Expeller oil press can change from one oilseed application to another, allowing for

Overview of the soybean process in the crushing industry

Abstract. A minimal residual oil content in the meal coming out of the hexane extractor is a clear benefit for a crushing plant; the more oil yield the better revenue for the crusher. In a modern and efficient extraction plant, a residual oil content ≤ 0.5% for soybean meal is expected.

Expanding and Expelling. Home Edible Oil Processing. Although mechanically the machines used to perform the expanding and the expelling functions share a number of common features, they serve completely different purposes. The expander is a unit assigned to seed or product preparation, whereas the expeller is the machine for mechanical oil

- What is a soy crush trade?

- This is the trade typically used by hedgers. Buying the crush, which is also known as the reverse crush, means buying Soybean Meal and Soybean Oil, and selling Soybeans. This may be used by traders who anticipate movements in the market that could make this strategy advantageous.

- Can a press cake be used for soybean seeds?

- Although it is not used for soybean, the mechanical press process is applied today for seeds with high oil content like sunflower, rapeseed etc., in general for pre-pressed purpose; the intermediate residual oil content in press cake is about 20%.

- How is soybean oil made?

- During the crush process, soybeans are cracked to remove the hull and then rolled into flakes, which are then soaked in a solvent and put through a distilling process to produce pure crude soybean oil. After the oil has been extracted, the soybean flakes are dried, toasted and ground into soybean meal.

- What is a crush spread in the soybean market?

- One of the most common spread trades in the soybean market is the crush spread. Soybeans are processed into soybean meal and soybean oil through a process known as crushing. The crush spread is the difference between the value of soybeans and its byproducts, and is considered a gauge of the potential profit margin for soybean processors.